Top 10 Machinery Partners for Your Business Success?

In the ever-evolving machinery industry, finding the right machinery partner can be a game changer for your business. Renowned expert, Mark Johnson, states, “Collaboration with the right machinery partner unlocks opportunities for innovation.” His insight highlights the importance of selecting a partner who understands your specific needs and can provide tailored solutions.

Choosing a machinery partner involves more than just cost. It requires a deep understanding of equipment capabilities and industry trends. The ideal partner not only supplies machinery but also offers support and expertise. However, businesses often overlook this crucial aspect. Many focus solely on price and miss the value added through a strong partnership.

Reflecting on this, companies should evaluate their current partnerships. Are they truly adding value? A successful machinery partnership should enhance efficiency and productivity. Businesses must be willing to invest time in assessing potential partners. The right machinery partner can drive growth and innovation, paving the path to lasting success.

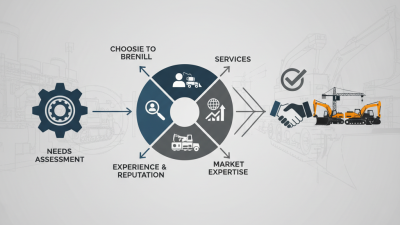

Identifying the Right Machinery Partners for Your Business Needs

When selecting machinery partners, it’s crucial to align their strengths with your business needs. Start by assessing the specific requirements of your operations. Are you in manufacturing, agriculture, or construction? Each sector demands different machinery and capabilities. Consider factors like technology, efficiency, and reliability. A partner with expertise in your industry can make a significant difference.

Building a partnership requires a deeper understanding beyond initial meetings. Visit their facilities, observe their equipment, and engage in discussions about their process. Look for transparency and a willingness to adapt to your needs. Sometimes, a perfect match isn't apparent at first. Differences in communication styles or service responsiveness can pose challenges. Open dialogue can help clarify these issues.

It's also wise to reflect on past partnerships. Think about what went wrong or right. Were there gaps in support? Did the equipment meet long-term performance expectations? Find partners willing to engage in continuous improvement. A good partnership can evolve and grow, but it requires commitment on both sides. Achieving the right fit may take time, but the investment can lead to substantial rewards.

Key Criteria for Selecting Reliable Machinery Partners

Selecting reliable machinery partners is crucial for business success. Start by examining their industry experience. A partner with a solid track record can provide insights into the best practices and emerging technologies. Look for partners who have worked with similar businesses or in your sector. This familiarity often leads to more efficient collaboration.

Next, consider quality standards and certifications. A partner should meet specific quality benchmarks to ensure your machinery performs reliably. Additionally, a willingness to provide references is essential. Speaking to past clients can reveal both strengths and weaknesses. Sometimes, a partner may seem perfect on paper but lacks essential support services, which can be critical for long-term operations.

A strong communication line is another vital criterion. Partners must be responsive and transparent about their processes. Sometimes, delays can lead to unresolved issues, and clear communication is key. Reflecting on past experiences can guide better choices in the future. Partners should also adapt to changes in your business needs, showing flexibility in their offerings. A rigid partner may not empower your growth effectively.

Assessing the Value of Manufacturer Experience and Reputation

Choosing the right machinery partner is crucial for success. A manufacturer’s experience can greatly impact the reliability of equipment. When assessing potential partners, look at their track record. Years in the industry matter. A well-established company often brings stability and expertise. Yet, it’s easy to overlook newcomers who may offer innovative solutions.

Reputation also plays a vital role. Customer reviews and testimonials provide insight into a manufacturer’s reliability. Consider how quickly they respond to issues. Timely support can prevent costly downtimes. Some companies boast about their achievements but lack evidence in practice. Evaluating the balance between claims and actual performance is necessary.

Partnering with a manufacturer is a big decision. Mistakes can lead to inefficient operations. Take time to research and discuss with peers. Understanding the value of experience and reputation will guide your choice. Keep in mind that not every established name is a perfect fit. Reflect on what your business truly needs.

Exploring Innovative Technologies Offered by Machinery Partners

In the competitive landscape of machinery, innovative technologies can make a significant difference. Automated systems are gaining traction. They streamline operations and reduce labor costs, but they require careful implementation. Many companies struggle to adapt to new software interfaces. Training staff can be time-consuming and expensive. This is a challenge that needs addressing for seamless adoption.

Another interesting area is predictive maintenance. Machinery equipped with sensors can analyze performance data in real-time. This helps in anticipating failures before they happen. However, not all businesses are ready to invest in such technologies. Some might not see immediate benefits and fail to understand long-term gains. New technology needs a cultural shift in how companies view equipment management.

Collaboration tools are also evolving. They allow for better communication between teams, whether onsite or remotely. Yet, reliance on these tools can lead to issues with information overload. Miscommunication may still occur, even with the best technologies. Reflecting on these tools' effectiveness is crucial for proper utilization. Each innovation brings opportunities, but also challenges that must not be overlooked.

Top 10 Innovative Technologies in Machinery for Business Success

Building Long-Term Relationships with Machinery Suppliers

Building strong relationships with machinery suppliers is crucial for business success. According to a report by the Manufacturing Institute, 70% of manufacturers cite supplier relationships as key to operational efficiency. Long-term partnerships can lead to consistent quality and cost savings. Many businesses overlook this aspect, often switching suppliers for minor savings without considering the long-term impact.

Fostering communication is essential. Regular meetings can help address concerns early. A survey showed that 65% of companies found improved product quality after establishing open lines of communication with suppliers. It’s not just about price; it’s about mutual growth. Suppliers who understand your needs can provide tailored solutions. However, some businesses still prefer a transactional approach, missing out on valuable insights.

Investing time in these relationships can yield significant returns. A report indicated that businesses with solid supplier bonds reported a 20% increase in productivity. Still, many partners face breakdowns in trust. Reflecting on past experiences can help improve future interactions. Balancing negotiation and collaboration is key. Developing a partnership is a journey, not a destination.

Related Posts

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs

-

Top 10 Heavy Equipment Broker Tips for Successful Transactions?

-

How to Choose the Right Heavy Equipment Broker for Your Needs

-

Why Choose a Heavy Equipment Trader for Your Construction Needs?

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project