Top Textile Machinery Innovations Transforming the Industry Now?

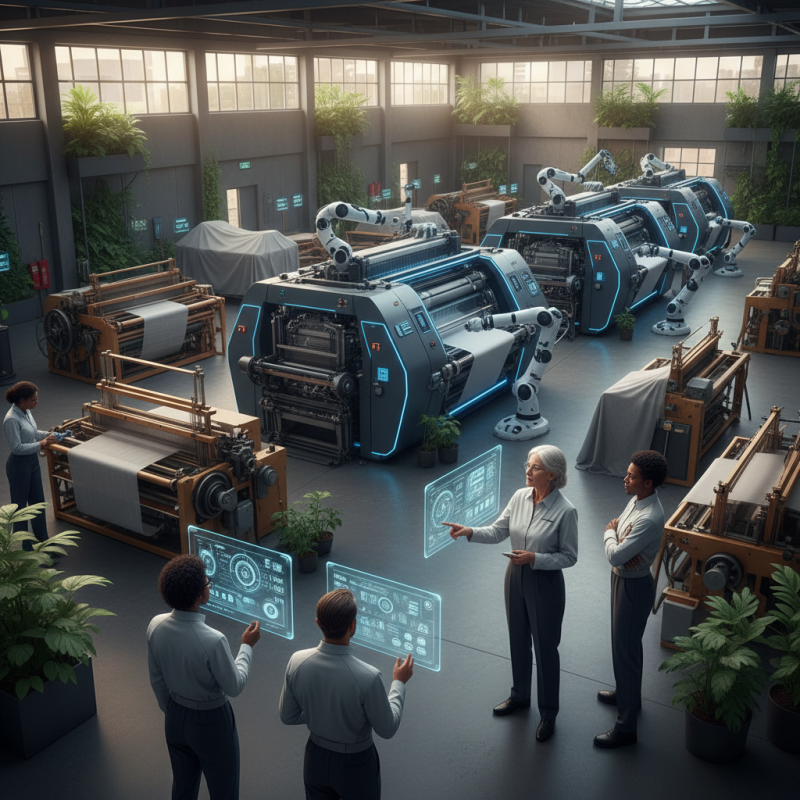

In the ever-evolving landscape of textile machinery, innovations are reshaping the industry. Renowned expert Dr. Emily Heller once said, “The future of textile machinery is in automation and sustainability.” This statement rings true as manufacturers embrace new technologies.

Advanced machinery enhances efficiency and reduces waste. However, the transition is not without challenges. Many companies struggle to adopt these innovations due to high costs and technical expertise requirements. Balancing investment with traditional methods often leaves manufacturers at a crossroads.

The potential for smart textile machinery is immense. Yet, many in the industry hesitate. They reflect on their current practices while contemplating what the future holds. The journey toward modernization is complex, but necessary for growth and sustainability.

Recent Advancements in Textile Machinery Technologies

The textile machinery industry is witnessing revolutionary advancements. Recent reports suggest that automation in textile production is increasing by 30% annually. This shift is driven largely by the integration of AI and machine learning, which enhances efficiency in processes like weaving and dyeing. These technologies can predict maintenance needs, reducing downtime significantly.

For manufacturers, investing in smart machines not only boosts productivity but also minimizes waste. Estimates show that implementing these technologies can lead to a 25% reduction in material waste. However, the high upfront costs of automation can be a barrier for smaller companies. Many are still hesitant, unsure if the long-term savings outweigh initial expenditures.

Tips: Embrace gradual upgrades. Transitioning to digital technologies can be overwhelming. Start with one area, like inventory management, before overhauling entire systems. Engage with employees during this process. Their feedback can provide crucial insights. Balancing traditional methods and new technology can lead to unique solutions. But remember, not every innovation may fit within your current production model. Assess your specific needs carefully.

Key Innovations Driving Efficiency in Textile Production

The textile industry is undergoing rapid transformations. Innovative machinery is at the heart of this evolution. These advancements aim to boost efficiency in textile production. Automated systems reduce labor costs significantly. They also increase production speed dramatically. These machines can handle various fabrics, creating more diverse products.

Smart technology plays a crucial role too. Sensors and data analytics optimize processes. They monitor every step, minimizing waste. However, this integration poses challenges. Not all workers adapt quickly to these changes. Training is essential, yet often overlooked. Balancing automation and human skill sets is vital.

Sustainability is another key focus. New machines are designed to consume less energy. They also utilize eco-friendly materials. While these innovations are promising, they require further refinement. Companies must invest thoughtfully. The road to fully efficient and sustainable production remains complex.

Sustainability Features in Modern Textile Machinery

In recent years, the textile industry has faced immense pressure to adopt sustainable practices. Modern machinery plays a pivotal role in this shift. One crucial feature is the use of energy-efficient technologies. These machines consume less energy, reducing the overall carbon footprint. The ability to recycle water during the manufacturing process is another significant advancement. This minimizes waste and ensures vital resources are conserved.

Another innovation is the integration of eco-friendly materials. Some machines can now process organic fibers or recycled textiles with greater ease. This reduces dependence on virgin materials and promotes a circular economy. However, not all manufacturers have embraced these technologies. The investment cost can be high, and some may hesitate to change their traditional methods.

Still, the urgency for sustainability cannot be ignored. As consumers demand more eco-conscious products, the industry must adapt or risk obsolescence. Continuous reflection on these advancements is necessary. Only then can the textile sector position itself for a more sustainable future. The road ahead is challenging, but progress is being made in these transformative innovations.

Automation and Robotics: The Future of Textile Manufacturing

The textile industry is undergoing a significant shift with automation and robotics at the forefront. Recent studies indicate that automation could increase productivity by up to 30% in textile manufacturing. Machines equipped with AI can process data in real-time, leading to quicker decision-making. This transformation allows for better inventory management and reduced waste, essential for sustainability.

However, the transition to automation isn't without challenges. Many workers feel threatened by job loss. A survey found that 70% of textile workers are concerned about their future roles. Automation should complement human skill rather than replace it. Finding the right balance is key.

Tips: Invest in training programs for your workforce. Upskilling can help employees adapt to new technologies. Foster a culture of collaboration between machines and humans. Automation should enhance creativity, not stifle it. Embrace these changes but remain aware of workforce sentiments and industry dynamics.

Top Textile Machinery Innovations Transforming the Industry Now

Impact of Smart Technologies on Textile Machinery Design

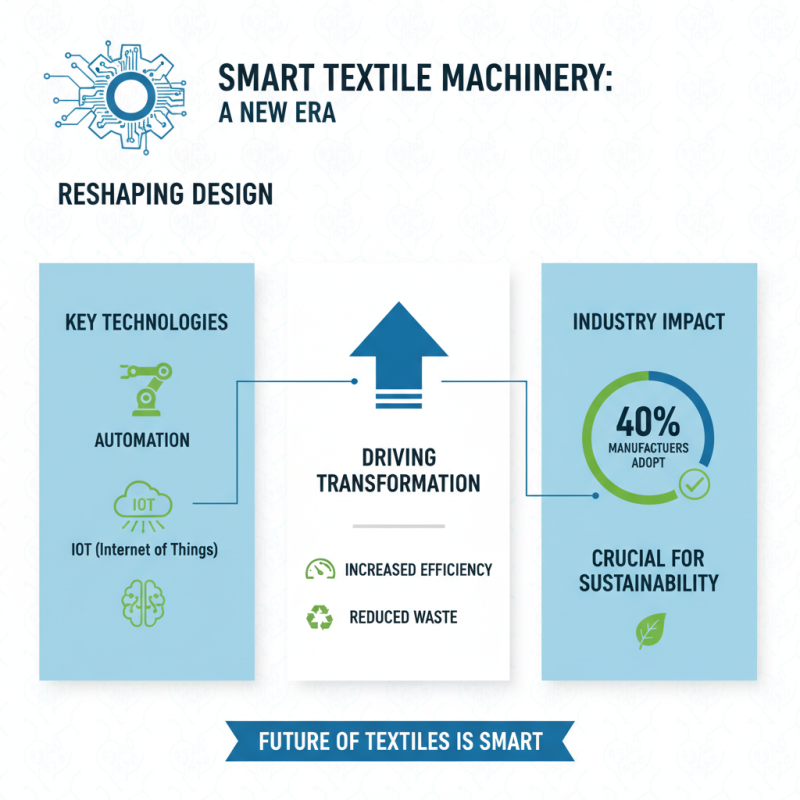

Smart technologies are reshaping textile machinery design. Automation, IoT, and AI play significant roles. A recent report noted that 40% of manufacturers now leverage these technologies. They increase efficiency while reducing waste. This transformation is crucial in an industry striving for sustainability.

Integrating smart devices allows real-time monitoring. For example, sensors can detect fabric defects instantly. This capability cuts down on production errors. However, some companies face challenges in adapting. Legacy machines often struggle to integrate with modern technologies.

The impact is profound. Data suggests that automation can reduce labor costs by up to 30%. Yet, this shift raises questions about job displacement. Balancing innovation with workforce stability remains a critical concern. The industry must navigate these complexities to benefit from advancements in technology.

Related Posts

-

Top 10 Textile Machinery Trends and Innovations for 2026

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

How to Choose the Best Plastic Recycling Machine for Your Needs?

-

10 Essential Tips for Choosing Machinery and Equipment for Your Business?

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders

-

2026 Top Construction Equipment Innovations You Need to Know?