Top Surplus Industrial Equipment Trends Transforming the Market Today?

The market for surplus industrial equipment is evolving rapidly. This shift reflects broader changes in manufacturing and resource management. Manufacturers are rethinking their strategies. They seek cost-effective solutions amidst economic uncertainty.

Emerging trends influence how businesses approach surplus industrial equipment. Technology plays a pivotal role, streamlining operations and enhancing efficiency. Companies focus on sustainability, seeking to reduce waste. However, some firms struggle to adapt to these new trends.

Market dynamics reveal a mixed picture. Not all businesses can leverage the benefits of surplus equipment. Challenges remain in understanding value and quality. As the industry transforms, stakeholders must learn to navigate these complexities. Embracing innovation will be crucial for success in this competitive landscape.

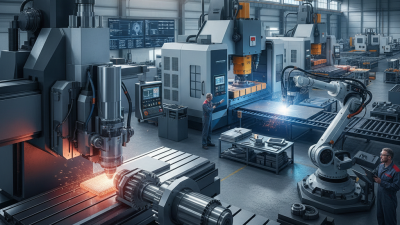

Emergence of Smart Technologies in Industrial Equipment Surplus Market

The emergence of smart technologies is revolutionizing the surplus industrial equipment market. IoT-enabled devices are enhancing efficiency and connectivity. According to a recent industry report, the market for smart industrial equipment is projected to reach $200 billion by 2027, showing a steady growth rate of 10% annually. This growth is driven by the need for increased productivity and reduced operational costs.

However, not all companies are adapting quickly. Many smaller firms struggle to integrate these advanced technologies. They may lack the necessary infrastructure or expertise. As a result, they risk falling behind larger organizations that leverage smart capabilities. Sometimes, the transition to smart technologies leads to confusion and inefficiencies, especially in older legacy systems that resist modernization.

Data analytics is another significant trend shaping this market. Companies are now analyzing equipment usage patterns to improve maintenance schedules. A survey found that 70% of organizations using data analytics reported reduced downtime. Yet, reliance on data can also create blind spots if not managed properly. Poor data quality can skew results, leading to misguided decisions. Balancing data insights with human judgment is essential in this evolving landscape.

Top Surplus Industrial Equipment Trends Transforming the Market Today

This chart illustrates the current trends in the surplus industrial equipment market, highlighting the increasing interest in smart technologies and automation solutions. As industries prioritize efficiency and sustainability, these trends are shaping the future landscape.

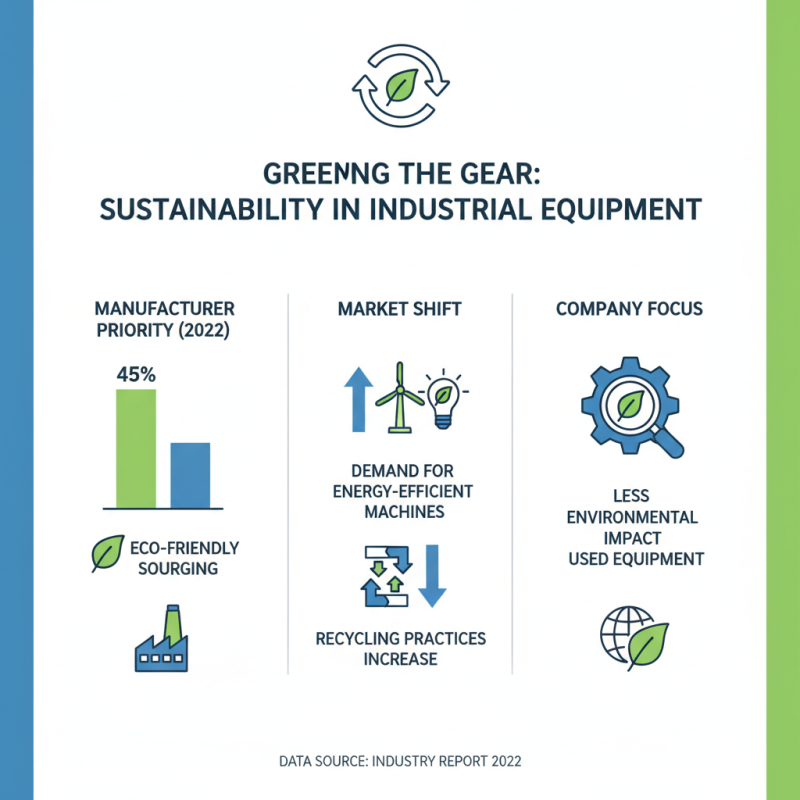

Impact of Sustainability Trends on Surplus Industrial Equipment Demand

Sustainability trends are reshaping the surplus industrial equipment market significantly. In 2022, approximately 45% of manufacturers prioritized eco-friendliness in sourcing decisions. This shift drives demand for energy-efficient machines and recycling practices. Companies are increasingly seeking used equipment that has less environmental impact.

Data indicates that 30% of industrial equipment buyers now prefer pre-owned assets. These buyers often consider life cycle costs over initial purchase prices. They focus on the carbon footprint of operating machinery. Green certifications and energy ratings are vital in evaluations. However, not all surplus equipment meets these new standards.

This evolving landscape requires reflection on existing inventory. Companies face challenges in identifying sustainable options among available surplus equipment. Those who adapt quickly to these trends gain a competitive edge. Yet, others may struggle to align their offerings with market expectations. The future demands innovation and a commitment to sustainability.

The Role of E-commerce Platforms in Surplus Equipment Sales

The rise of e-commerce platforms is shaping surplus industrial equipment sales significantly. Data from recent industry reports indicates that online sales in this sector have surged by over over 30% in the past year. Buyers appreciate the convenience of purchasing equipment from their devices. Detailed product listings and virtual tours help customers make informed decisions.

Many sellers are now facing challenges in keeping their inventory updated. With numerous platforms available, effective management is crucial. Reports show that items listed without clear pictures or descriptions sell much less frequently. Sellers often overlook this detail, affecting their overall sales performance. Transparency is key in online transactions.

The evolving landscape also poses risks. Some platforms lack robust vetting processes, leading to potential fraud. Industry experts emphasize the importance of due diligence. Buyers should verify seller credentials before proceeding. While e-commerce expands market access, it also invites new challenges that require careful consideration.

Shifts in Global Supply Chains Affecting Surplus Equipment Availability

The global supply chains have shifted dramatically in recent years. This change is affecting the availability of surplus industrial equipment. Factors like geopolitical tensions and the pandemic disrupted traditional routes. Companies now face longer lead times and rising costs. Consequently, businesses need to adapt quickly to these evolving conditions.

Surplus equipment, once easily accessible, is now harder to find. The unexpected demand surge leaves many seeking solutions. Some organizations are turning to online platforms for better access. However, not all listings reflect current market conditions accurately. It's challenging to gauge true value amidst fluctuating availability.

Moreover, the distribution of surplus equipment isn't even. Some regions face scarcity, while others are oversupplied. It's crucial for buyers to research comprehensively. Their decisions must factor in these inequities. Effective sourcing strategies require vigilance and adaptability in an uncertain market.

Top Surplus Industrial Equipment Trends Transforming the Market Today

| Trend | Description | Impact on Availability | Regional Insights |

|---|---|---|---|

| Increased Automation | The rise in automated manufacturing processes leading to surplus equipment. | Higher availability of surplus machinery as firms upgrade. | North America; Europe. |

| Sustainability Initiatives | Efforts to reduce waste and increase reuse of machinery. | Decrease in available surplus as equipment is refurbished. | Global; especially in developed markets. |

| Global Supply Chain Disruptions | Difficulties in sourcing new equipment create demand for surplus. | Increased demand for surplus equipment due to delays in new deliveries. | Asia; North America. |

| Technological Advances | Emergence of new technologies leading to faster obsolescence of older models. | More surplus from older technologies as companies upgrade. | Global, with significant trends in Europe and the US. |

Increased Focus on Asset Recovery and Optimization Strategies

The trend of asset recovery and optimization strategies is crucial in today's industrial equipment market. Companies are increasingly focused on maximizing the value of underutilized assets. According to a recent report, about 60% of industrial firms now emphasize these strategies to enhance their financial performance.

Effective asset recovery involves identifying equipment that is no longer needed and repurposing it. This approach not only reduces waste but also allows companies to maintain cash flow. Data indicates that businesses can recover up to 30% of costs through effective resale and recycling programs. However, many still struggle with efficient implementations.

Moreover, optimization strategies require a thorough analysis of existing assets. This analysis can involve upgrading older equipment or adjusting operational procedures to improve efficiency. A substantial 40% of firms report that inefficient asset management leads to wasted investment. The challenge lies in balancing immediate needs with long-term sustainability. It’s vital for companies to rethink their strategies and embrace innovative solutions to thrive in this evolving market landscape.

Related Posts

-

2026 How to Choose the Right Earth Moving Equipment?

-

Top 5 Second Hand Industrial Equipment Options for Your Business Needs

-

How to Choose the Right Metal Working Machines for Your Projects

-

Top 10 Textile Machinery Trends and Innovations for 2026

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

How to Choose the Right Heavy Equipment Broker for Your Needs