What is Heavy Machinery and How is it Used in Industry?

Heavy machinery plays a crucial role in various industries. These powerful machines help with construction, mining, and manufacturing tasks. They are designed to perform heavy lifting and move large materials efficiently.

In the construction industry, heavy machinery includes excavators, bulldozers, and cranes. Each piece has a specific function that increases productivity. For example, excavators dig deep foundations while bulldozers push earth to clear sites. However, operators must be trained carefully to avoid accidents.

In manufacturing, heavy machinery often includes forklifts and industrial presses. These machines streamline production processes, making operations faster. Yet, reliance on heavy machinery can lead to challenges, such as equipment breakdown and maintenance costs. It is vital for companies to balance efficiency with sustainability, reflecting on the impact of machinery on both their workforce and the environment.

Definition and Overview of Heavy Machinery

Heavy machinery encompasses a range of powerful equipment designed for construction and heavy-duty tasks. This category includes

excavators, bulldozers, and cranes. These machines are crucial in various industries like construction, mining, and agriculture. Their sheer size and strength allow them to perform tasks that would be impossible for humans alone.

For example, an excavator can dig deep into the earth, moving tons of material quickly and efficiently.

In industrial settings, heavy machinery is essential for improving productivity. Operators need training to handle such machines safely. Misuse can lead to costly mistakes or accidents, impacting projects and workers' safety.

Additionally, maintenance is vital. Neglecting proper upkeep can result in breakdowns or inefficiency.

Industries often face challenges related to the aging equipment.

Upgrading to the latest technology might be expensive, yet it can increase productivity and safety.

Heavy machinery is more than just equipment; it’s a lifeline for many industries. Each piece serves a distinct purpose, transforming the landscape of work.

However, there is an ongoing debate about the balance between automation and human roles in these environments.

As technology evolves, careful consideration is needed to ensure safety and efficiency without sacrificing jobs.

Types of Heavy Machinery Used in Various Industries

Heavy machinery plays a crucial role in various industries, including construction, mining, and agriculture. These machines enhance productivity and efficiency. Among the most common types are bulldozers, excavators, cranes, and dump trucks. Each type serves a distinct purpose but contributes to overall operational effectiveness.

Construction sites utilize excavators extensively for digging and earthmoving. According to industry reports, the global excavator market is projected to grow by over 4% annually. In mining, bulldozers are vital for clearing land and moving materials. They provide the strength needed to tackle tough terrains. Cranes, meanwhile, are essential for lifting heavy loads to great heights, revolutionizing construction processes.

Tips: Regular maintenance of heavy machinery extends its lifespan. Set a schedule to check oil levels and track wear and tear. Also, consider training for operators. Skilled operators maximize efficiency and reduce safety risks. It’s crucial to address training gaps, as inadequate skills can lead to costly errors.

In agriculture, tractors help with planting and harvesting. They aid in effective land use, impacting yield positively. Reports indicate that mechanized farming can increase production by up to 30%. However, reliance on machinery could lead to soil compaction issues over time. Balancing technology and environmental conservation is essential for sustainable growth.

What is Heavy Machinery and How is it Used in Industry?

| Type of Heavy Machinery | Used In | Primary Function | Example Applications |

|---|---|---|---|

| Excavator | Construction, Mining | Digging, Lifting | Site preparation, Demolition |

| Bulldozer | Construction, Road building | Moving earth, Material Handling | Clearing land, Grading |

| Crane | Construction, Shipping | Lifting heavy loads | Building structures, Loading containers |

| Forklift | Warehousing, Logistic | Transporting materials | Moving pallets, Stacking |

| Backhoe Loader | Construction, Agriculture | Digging, Loading | Trenching, Material transport |

Key Applications of Heavy Machinery in Construction

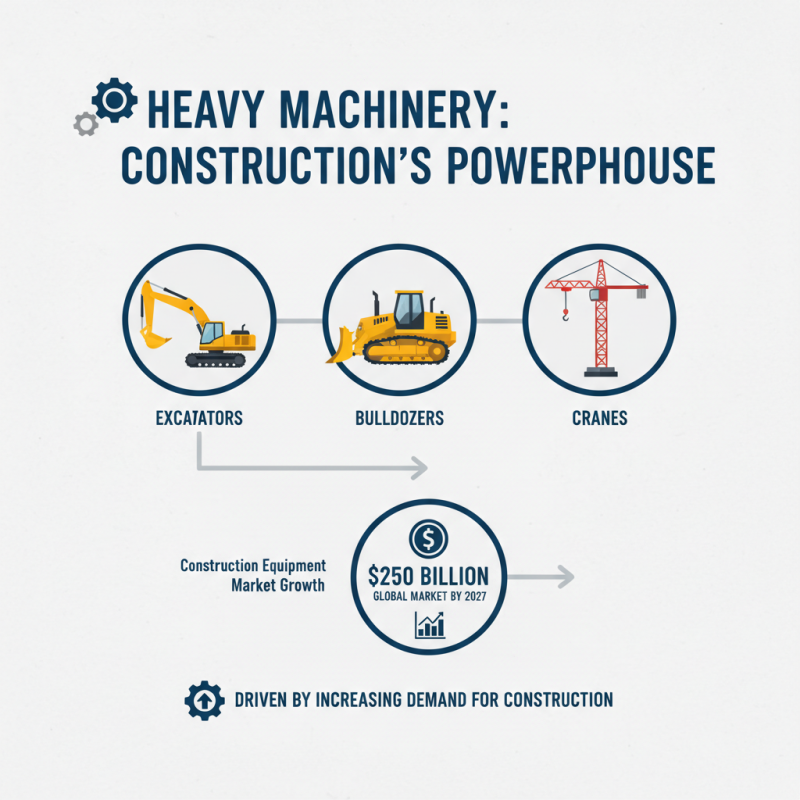

Heavy machinery plays a crucial role in the construction industry. It includes equipment like excavators, bulldozers, and cranes. According to the Global Construction Equipment Market report, the sector is expected to reach $250 billion by 2027. This growth reflects the increasing demand for construction activities.

Excavators are vital for digging and site preparation. They can move large amounts of earth efficiently. It’s reported that a standard excavator can dig up to 2.5 cubic meters of soil per hour. However, operating these machines requires skilled operators. Inexperienced operators can lead to accidents. Safety training is essential to ensure everyone’s well-being on-site.

Cranes elevate heavy materials to great heights. They are often used for steel framework and roof installations. The industry sees accidents due to improper crane use, resulting in injuries. Reports indicate that around 25% of construction site fatalities come from crane-related incidents. This reflects a pressing need for improved safety protocols. Heavy machinery can enhance productivity, yet it demands responsible use and proper training.

Safety Protocols and Best Practices for Operating Heavy Machinery

When operating heavy machinery, safety is paramount. Proper training is crucial. Operators should understand the equipment they are using. They must be aware of their surroundings to prevent accidents. A common mistake is ignoring potential hazards. Always keep a safe distance from others while operating machines.

Tips: Always wear appropriate personal protective equipment. This includes helmets, gloves, and steel-toed boots. Regularly inspect the machinery before use. Report any damages immediately.

Communication is also vital. Ensure that operators signal clearly. Workers must understand these signals to avoid misunderstandings. Clarity can often save lives. Some may feel rushed to complete tasks, but taking time to communicate properly can prevent accidents.

Tips: Establish a designated area for machinery operations. Limit access to only essential personnel. Regular safety drills can keep awareness high. Being prepared is better than reacting after an incident.

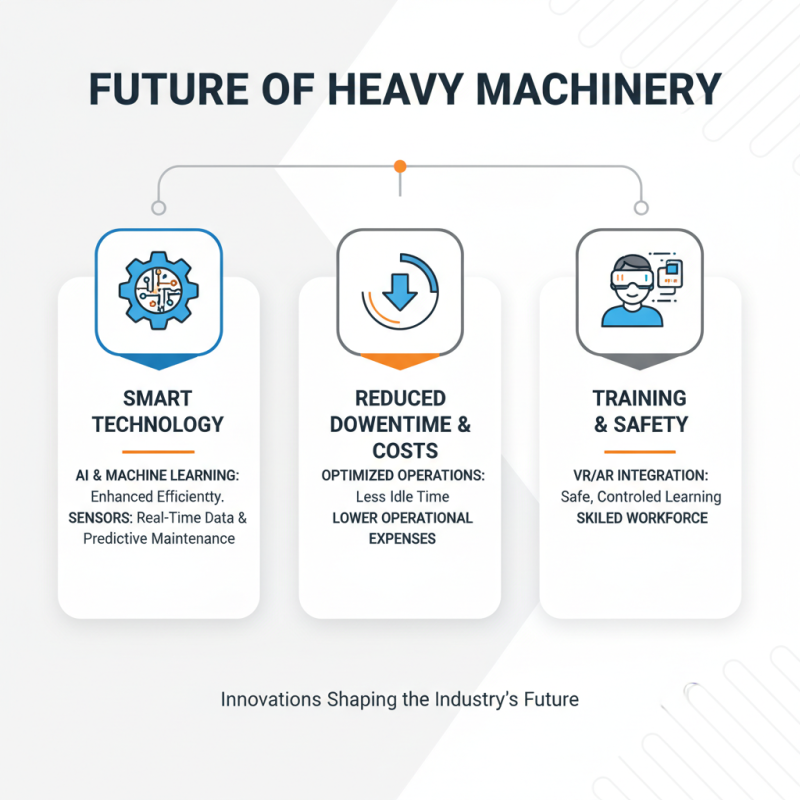

Future Trends and Innovations in Heavy Machinery Technologies

The heavy machinery industry is witnessing significant innovations that shape its future. Smart technology is transforming these powerful machines. AI and machine learning enhance efficiency. Sensors collect real-time data, leading to predictive maintenance. This reduces downtime and operational costs. The integration of virtual and augmented reality is becoming popular for training. Workers can learn to operate machines safely and effectively in a controlled environment.

Sustainability is another focus. Companies are developing eco-friendly machinery. These machines use less fuel and emit fewer gases. New materials make equipment lighter and more efficient. Electrification is emerging, offering quieter and cleaner alternatives. However, the challenge lies in the initial costs and infrastructure. Transitioning to greener technologies requires investment and time.

Despite advancements, there are hurdles. The industry faces a skills gap. Many workers lack the knowledge to operate next-gen machinery. Continuous training is essential to bridge this gap. Regulations also play a crucial role in shaping innovations. Balancing safety standards and technological advancements is complex. The future of heavy machinery depends on overcoming these challenges. It will be a journey of adaptation and reflection.

Related Posts

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

-

How to Choose the Right Industrial Machinery for Your Business Needs in 2025

-

10 Essential Tips for Choosing Machinery and Equipment in Your Business?