10 Essential Tips for Choosing Machinery and Equipment for Your Business?

Choosing the right machinery and equipment is crucial for any business. According to industry expert John Smith, “The wrong choice can lead to inefficiencies and increased costs.” This highlights the importance of making informed decisions when selecting machinery and equipment.

When considering machinery and equipment, think about your specific needs. Different businesses require different tools. It's not just about grabbing the most advanced option. You must assess your production goals and demands. Sometimes, simpler solutions work better.

Pay attention to both quality and cost. You may be tempted to go for cheaper options, but this could backfire. Quality machinery and equipment often lead to higher productivity and lower maintenance costs over time. Reflection on past purchases may help highlight this point. Ensure you do your research to find the balance that works for you.

Identifying the Specific Needs of Your Business Operations

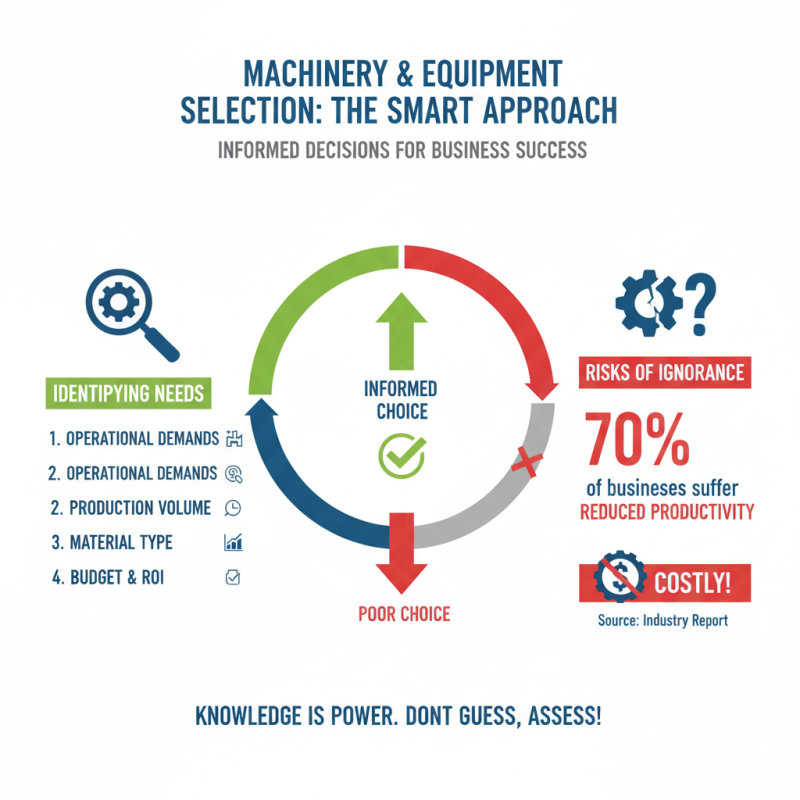

Identifying the specific needs of your business operations is crucial when selecting machinery and equipment. Understanding your operational demands helps you make informed decisions. According to an industry report, nearly 70% of businesses that fail to assess their equipment needs suffer from reduced productivity. This is a clear indication that ignorance can be costly.

One effective tip is to conduct a thorough needs assessment. Examine your current workflows and pinpoint inefficiencies. This could reveal a need for automation or newer technology. Another study indicates that businesses that invest in the right machinery report a 25% increase in operational efficiency. This shows the importance of aligning your equipment with your core tasks.

Consider engaging your team in this process. Gathering diverse perspectives can uncover hidden challenges and opportunities. Encouraging feedback can lead to better decision-making. Moreover, prioritize equipment that offers versatility. Excessive specialization may hinder your ability to adapt in changing markets. Remember, the wrong choice could tie up resources unnecessarily, affecting your bottom line.

Evaluating Different Types of Machinery and Equipment Available

When evaluating different types of machinery and equipment for your business, start by understanding your specific needs. Consider what tasks you need the equipment to perform. This will help you narrow down options tailored to your operations. Think about the volume of work and the nature of the tasks. For example, heavy-duty machinery suits larger operations while smaller tools serve niche functions.

Next, evaluate durability and maintenance requirements. Some machines need frequent servicing, which can increase operating costs. Assess whether you can provide regular maintenance. You might need to hire additional personnel for upkeep. Also, think about the space available in your facility. Larger equipment requires more space, hindering workflow in limited environments.

Don’t forget the technology involved. Automated machines may enhance efficiency but also complicate training. Finding the right balance between manual and automated systems can be tricky. Lastly, consider sourcing options. Used equipment can be affordable but might need repairs. New equipment ensures optimal performance but comes at a higher cost. Prioritize features that align with your long-term goals rather than short-term savings.

10 Essential Tips for Choosing Machinery and Equipment for Your Business

Understanding Budget Constraints and Cost Analysis

When selecting machinery and equipment for your business, budget constraints play a crucial role. Many businesses overlook hidden costs. These costs can include maintenance, repairs, and operational expenses. Evaluate your budget carefully. A larger initial investment may lead to long-term savings. But, it can also strain your cash flow. Balance is key.

Cost analysis helps to identify the total cost of ownership. Factor in resale value and depreciation. Equipment might seem affordable now, but what about in five years? Assess your business needs. Will the machinery serve you well over time? Look for options that combine efficiency with durability. Sometimes, spending a bit more upfront can reduce operational hassles later.

Also, don't forget about financing options. Many businesses struggle due to overwhelming upfront costs. Consider leasing or loans to improve cash flow. Analyze your pricing strategy as well. Can you absorb the costs? Or will they drive prices higher? Reflect on these details. Each decision shapes your business's future.

Assessing Maintenance and Support Requirements

Choosing the right machinery and equipment is crucial for any business. Maintenance and support requirements are often overlooked. Yet, they can make or break your operational efficiency. According to industry reports, about 30% of equipment failures result from insufficient maintenance planning. This underscores the importance of assessing long-term support options before making a purchase.

When evaluating machinery, consider how easy it is to obtain parts and service. Is local support available? Are there reliable technicians nearby? A machine may shine in the showroom but can quickly become a burden without proper maintenance. Construction industry data suggests that companies with a robust maintenance program can reduce downtime by up to 25%.

Tip: Factor in maintenance training for your staff. Knowledgeable personnel can handle minor issues, saving time and costs. Another consideration is the warranty. A comprehensive warranty often reflects the manufacturer's confidence in the product. However, ambiguous terms can lead to disputes later. Always read the fine print and understand what is truly covered. Balancing equipment capability and maintenance support will ensure your business runs smoothly.

Researching Supplier Credibility and Customer Reviews

When selecting machinery and equipment, supplier credibility is crucial. Research different suppliers thoroughly. Check their history and experience. A company’s years in business often reflect reliability. Look for customer reviews and testimonials. These give insights into other buyers’ experiences. Don’t just focus on positive feedback. Pay attention to negative reviews too. They reveal possible issues.

Visit forums and industry websites to gather diverse opinions. A mix of viewpoints can paint a clearer picture. Are the suppliers responsive to concerns? Do they offer support after the sale? Reflect on these questions. Sometimes, a well-known brand may not provide the best service. Lesser-known suppliers can exceed expectations.

Consider reaching out to past clients of the supplier. Ask about their satisfaction with the equipment. Were there any unexpected challenges? Honest feedback can guide your decision. Remember, the best choice is not always the most glamorous one. Value for money often lies beneath the surface. Balancing quality, service, and cost is vital.

10 Essential Tips for Choosing Machinery and Equipment for Your Business

| Tip No. | Tip Description | Key Considerations | Customer Review Insights |

|---|---|---|---|

| 1 | Identify Your Business Needs | Understand specific requirements for machinery based on production processes. | Customers emphasize clarity in business requirements. |

| 2 | Research Supplier Credibility | Verify supplier’s background, years in business, and industry standing. | Positive reviews highlight reliability and trustworthiness. |

| 3 | Evaluate Customer Reviews | Look at feedback related to performance and after-sales support. | Customers frequently mention the importance of responsive support. |

| 4 | Consider Total Cost of Ownership | Analyze maintenance, operation, and energy costs over time. | Customers recommend considering long-term savings. |

| 5 | Check for Compliance and Safety Standards | Ensure machinery meets industry regulations and safety guidelines. | Reviews often stress the importance of compliance for safety. |

| 6 | Assess Technological Features | Look for innovative features that enhance productivity. | Customers appreciate modern technology that improves efficiency. |

| 7 | Consider Scalability | Choose equipment that can grow with your business needs. | Customers advise aiming for adjustable solutions. |

| 8 | Compare Multiple Quotes | Gather and compare prices from different suppliers. | Reviews suggest not settling for the first quote. |

| 9 | Seek Recommendations | Ask for referrals from trusted industry colleagues. | Customers find word-of-mouth valuable for decision-making. |

| 10 | Take Time to Test and Review | If possible, test the machinery before purchase. | Customers emphasize testing for suitability. |

Related Posts

-

10 Essential Tips for Choosing Machinery and Equipment in Your Business?

-

What is Heavy Machinery and How is it Used in Industry?

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

2026 Best Heavy Machinery Trends to Watch for in the Industry?

-

Top Surplus Industrial Equipment Trends Transforming the Market Today?