2026 How to Choose the Right Plastic Extruder Machine for Your Needs?

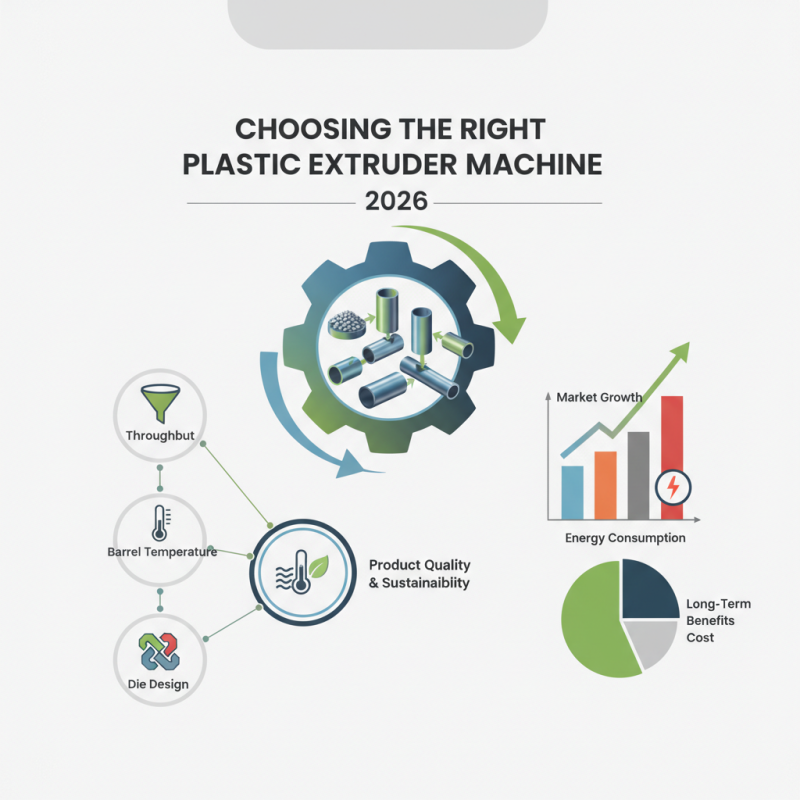

Choosing the right plastic extruder machine can be a daunting task. The global plastic extrusion market reached USD 4.56 billion in 2022 and is projected to grow significantly. With such rapid expansion, selecting an optimal machine is vital for operational success.

A plastic extruder machine is essential for transforming raw materials into usable products. Various factors define the effectiveness of these machines. Understanding throughput, barrel temperature, and die design becomes critical. Each detail can affect product quality, leading to increased costs in waste and rework.

Reports indicate that inefficient machines can lead to energy consumption increases of up to 25%. Businesses must assess their specific needs carefully. Investing in a plastic extruder machine is not just about cost; it involves considering long-term benefits and sustainability. Each choice carries weight, influencing productivity and environmental impact.

Factors to Consider When Selecting a Plastic Extruder Machine

Selecting the right plastic extruder machine is crucial for your production needs. Consider the

material type you will work with. Different materials require specific temperatures and screws. Understand the properties of each material to choose the best fit.

Another key factor is the production volume. Larger volumes may require machines with higher throughput. If your production needs fluctuate, consider machines that allow for easy adjustments. Efficiency is vital to reduce costs and increase profitability.

Tips: Always check energy consumption ratings. Efficient machines can save money long-term. Assess the machine's maintenance needs. A high-maintenance machine can lead to frustrations down the road. Don’t ignore the technical support available. It can greatly impact your operations.

Types of Plastic Extruder Machines and Their Applications

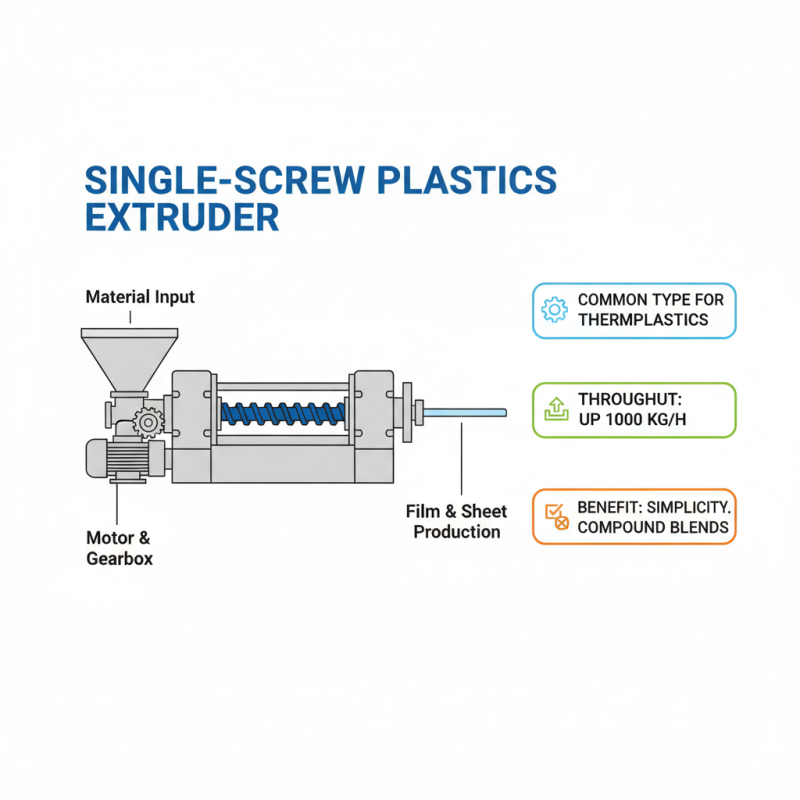

When selecting a plastic extruder machine, it's crucial to understand the different types available and their specific applications. Single screw extruders are the most common type. They are efficient for thermoplastic materials and are often used in film and sheet production. Industry data indicates that single screw extruders can achieve throughput rates of up to 1000 kg/h, depending on the material. Their simplicity is a benefit, but they may struggle with certain compound blends.

Another option is the twin-screw extruder, which excels in mixing and compounding materials. This type can handle a wider variety of formulations and is often preferred for applications like masterbatch production. Reports show that twin-screw extruders can enhance product consistency, with mixing capabilities significantly improving. However, they come with higher costs and complexity. Choosing the right type depends on your production goals and budget.

In the realm of specialized extruders, options like co-extruders cater to specific needs. They allow the layering of materials, enhancing barrier properties. The versatility of co-extruders is impressive, but they require advanced setup and integration. Despite their efficiency, the learning curve can be steep. It's essential to weigh the benefits against the potential drawbacks of each type to ensure the best fit for your manufacturing needs.

Assessing Production Capacity and Efficiency Requirements

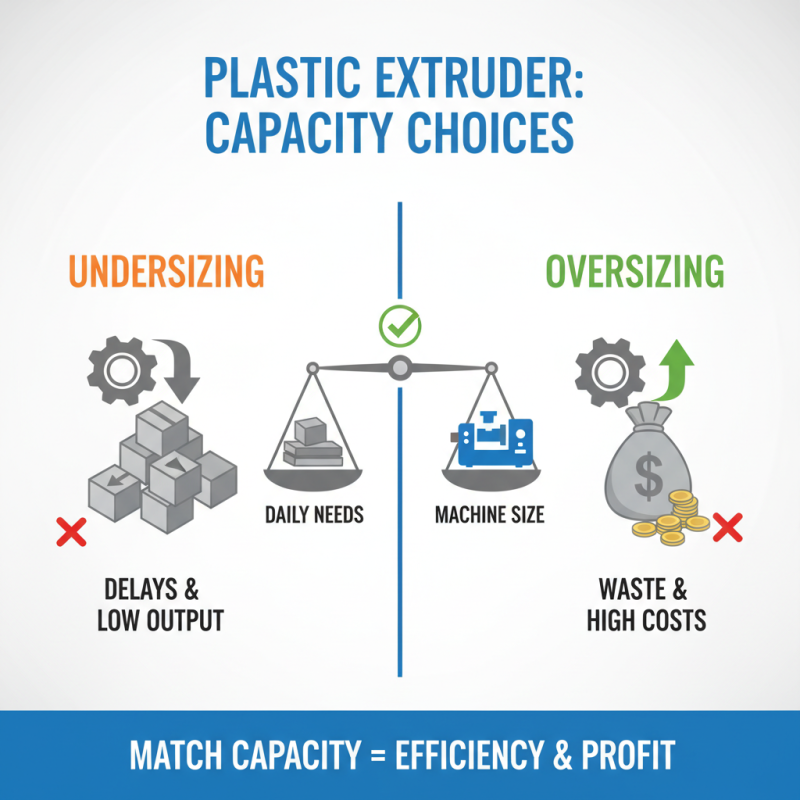

When choosing a plastic extruder machine, assessing production capacity is crucial. You should start by determining your daily output needs. Think about how many parts you produce each day and their sizes. This will help you choose the right machine. If you underestimate your needs, you may face production delays. On the other hand, oversizing can lead to excess costs.

Efficiency is equally important. Different machines offer varying levels of energy consumption and speed. A more efficient machine can reduce operational costs and improve profitability. Consider the materials you will work with. Not all machines handle every type of plastic effectively. Testing the extruder with your specific material ensures it meets your standards.

Meeting production demands can be challenging. You might find yourself needing to adjust settings frequently. Sometimes, fine-tuning the process is necessary for optimal results. Assessing your requirements now can prevent future headaches. Evaluate your choices carefully to find the best balance of capacity and efficiency.

Evaluating Material Compatibility for Your Extrusion Needs

When selecting a plastic extruder machine, material compatibility is crucial. Understanding the types of polymers you plan to extrude informs your choice. For instance, thermoplastics like PVC and PET have different processing requirements. According to a recent industry report, 70% of extrusion errors stem from improper material selection. This statistic emphasizes the need for careful evaluation.

Compatibility also affects temperature settings and screw design. Each material has a specific melting point and flow characteristics. Using a screw design tailored to your material enhances efficiency. An incompatible machine can lead to under-extrusion or clogging. Some machines offer flexibility for multiple materials, but the reality is that they may not perform well under all conditions. This could result in wasted resources.

Consider the scale of production too. Small-scale operations may favor machines that are easier to clean and switch between materials. A study showed that 65% of manufacturers experienced downtime due to cleaning issues. This is something to reflect on as you make your decision. Balancing performance, compatibility, and adaptability plays a key role in ensuring your extruder machine meets your needs effectively.

Budgeting and Cost Analysis for Purchasing a Plastic Extruder Machine

When considering the purchase of a plastic extruder machine, budgeting is crucial. Start by outlining your total budget. Consider not only the purchase price but also the operational and maintenance costs. These machines can be expensive, so allocating funds wisely is essential. Look at all costs: raw materials, utilities, and labor. Don't overlook the costs for potential upgrades or repairs.

Evaluating the budget requires honest assessment. Have you factored in future growth? A machine that fits today’s needs might not suit tomorrow’s demands. It's tempting to go for the cheapest option to save money, but this can backfire. A lower-priced machine may incur higher operational costs or fail to deliver quality output. Analyze the return on investment (ROI) carefully.

Consider financing options too. Not everyone can afford a large upfront payment. Explore leasing or loans to spread costs over time. As you budget, remember that cheaper isn't always better. Efficiency and quality often outweigh initial costs. Mistakes in budgeting can lead to bigger issues later. Assessing your needs and costs thoroughly is imperative for a successful purchase.

Related Posts

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders

-

2026 Best Heavy Construction Equipment for Efficient Project Management?

-

Why You Should Invest in a Plastic Recycling Machine for Your Business

-

Top Surplus Industrial Equipment Trends Transforming the Market Today?

-

Top 10 Best Construction Machines for Every Project?