How to Choose the Right Industrial Machinery for Your Business Needs in 2025

In the evolving landscape of industrial operations, the selection of the right industrial machinery plays a pivotal role in defining a business's efficiency and productivity. As we look toward 2025, industries must navigate a myriad of choices, each with distinct specifications, capabilities, and advancements. The right machinery can significantly enhance operational workflows, reduce downtime, and ultimately drive profitability, making it imperative for business leaders to understand their unique requirements and the technological advancements available.

As businesses increasingly integrate automation and advanced technologies into their processes, the importance of selecting appropriate industrial machinery cannot be overstated. Factors such as scalability, energy efficiency, and ease of maintenance will become critical in ensuring that your machinery meets not just current demands, but future growth as well. Furthermore, aligning machine selection with sustainability goals and industry standards will be essential in fostering a responsible business image while maximizing output.

Therefore, this guide aims to equip business owners and decision-makers with the insights needed to make informed choices about industrial machinery that aligns with their specific needs. By examining key considerations and emerging trends, organizations can prepare to invest wisely in machinery that not only meets today's challenges but also positions them favorably for the future of their respective industries.

Understanding Your Business Requirements for Industrial Machinery

Understanding your business requirements is crucial when selecting industrial machinery for your operations. The first step is to assess the specific tasks and processes that the machinery will support. Consider factors such as production volume, product specifications, and the complexity of operations. By clearly defining these requirements, you can ensure that the machinery you choose will enhance efficiency and productivity while fitting seamlessly into your existing workflow.

Another important aspect to consider is the scalability of the machinery. As your business evolves, your needs may change. Choose machinery that can adapt or expand to accommodate future growth, whether that means handling increased output or integrating new technologies. Additionally, evaluate the level of automation you require. Greater automation can lead to reduced labor costs and improved precision, but the right balance must be struck based on your workforce and operational goals. Taking the time to thoroughly understand these elements will empower you to make informed decisions and invest wisely in machinery that aligns with your long-term business objectives.

Evaluating Different Types of Industrial Machinery Available in 2025

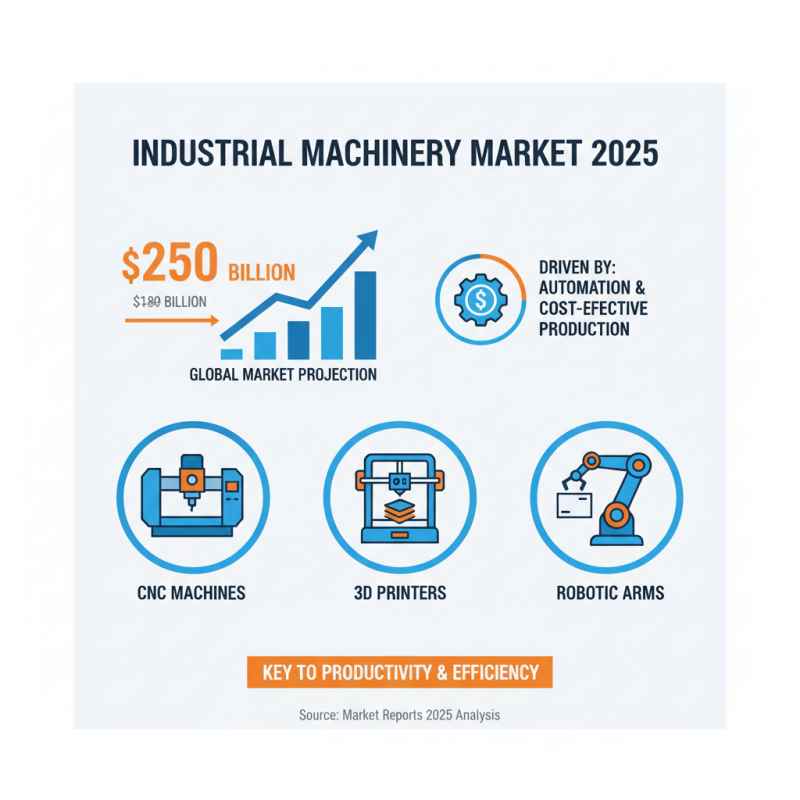

In 2025, companies looking to streamline their operations will need to carefully evaluate the various types of industrial machinery available to meet their specific business needs. A comprehensive analysis of market reports suggests that the global industrial machinery market is projected to reach approximately $250 billion by 2025, driven by advancements in automation and the increasing demand for cost-effective production solutions. Key types of machinery to consider include CNC machines, 3D printers, and robotic arms, each contributing significantly to productivity and efficiency.

CNC (Computer Numerical Control) machines remain crucial for precision machining and mass production, enabling manufacturers to create complex parts with minimal human intervention. According to a report by Deloitte, the adoption of CNC technology is expected to increase by 25% among small to mid-sized manufacturers in the next couple of years, highlighting its importance in staying competitive. Additionally, additive manufacturing, or 3D printing, is revolutionizing production processes by allowing for rapid prototyping and reduced material waste, presenting businesses with innovative ways to reduce overhead costs while enhancing customization capabilities. Moreover, the use of robotic arms is projected to rise, with McKinsey indicating that automation could replace up to 45% of manual tasks in various industries.

Considering these trends and technologies in industrial machinery will be pivotal for businesses aiming to optimize their operations in 2025. Understanding the specific benefits, costs, and integration potential of each type of machinery will aid companies in making informed decisions that align with their operational strategies and growth objectives.

Assessing Budget and Financial Considerations for Your Machinery Purchase

When selecting industrial machinery, a critical factor to consider is your budget and financial implications. A survey conducted by the National Association of Manufacturers (NAM) found that nearly 60% of manufacturers cite budget constraints as a significant hurdle in their purchasing decisions. It's essential to establish a clear financial plan that not only accommodates the upfront costs of machinery but also considers ongoing operational expenses, including maintenance, training, and energy consumption. Research indicates that operating costs can account for up to 70% of the total lifecycle cost of machinery, emphasizing the need for a comprehensive financial assessment.

Additionally, investing in advanced machinery may initially strain your budget, but it could lead to enhanced productivity and efficiency. According to a report by the World Economic Forum, companies that invest in innovative technologies can see productivity gains of up to 30%. Therefore, businesses must weigh the short-term financial strain against the potential for long-term savings and improved output. Utilizing financing options, such as equipment loans or leasing arrangements, can also help mitigate the immediate financial impact, allowing businesses to invest in the right machinery without compromising their cash flow. By conducting thorough financial evaluations, companies can make informed decisions that align with their operational goals and budgetary constraints.

Industrial Machinery Budget Allocation by Category (2025)

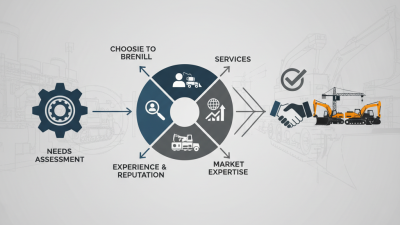

Researching Suppliers and Manufacturers for Reliability and Support

When selecting industrial machinery for your business, one of the most critical steps is researching suppliers and manufacturers to ensure reliability and support. Start by evaluating potential suppliers based on their reputation and track record within the industry. Look for companies that have been in business for several years and have a history of positive customer feedback. Online reviews, industry forums, and professional networks can provide valuable insights into the reliability of various suppliers.

In addition to reputation, it’s vital to consider the level of support a supplier offers. A trustworthy supplier not only provides quality machinery but also assists with installation, training, and ongoing maintenance. Assess their customer service capabilities by inquiring about response times and availability of technical support. Furthermore, check if they offer warranties or service contracts, as these can significantly enhance the overall value of your purchase. By conducting thorough research into suppliers and manufacturers, you can make an informed decision that aligns with your business needs and ensures long-term operational success.

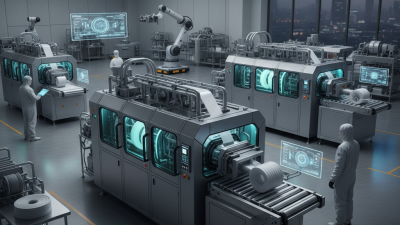

Integrating New Machinery with Existing Processes and Technologies

When selecting industrial machinery for your business in 2025, it's crucial to consider how new equipment will integrate with your existing processes and technologies. Smooth integration can enhance operational efficiency and minimize disruptions. Begin by mapping out your current workflow and identifying key areas where new machinery can add value without overhauling your existing setup. This step is vital in ensuring that your investment aligns with your operational goals.

**Tips:** Assess compatibility with existing systems by reviewing specifications and consulting with technical experts. Prioritize machinery that offers modularity, allowing for adjustments and expansions without extensive modifications.

Moreover, training your staff to work with both new and existing machinery is essential. Ensure a seamless transition by organizing workshops that familiarize employees with new technology while reinforcing their knowledge of current systems. This encourages a culture of continuous improvement and innovation.

**Tips:** Invest in training programs that emphasize hands-on experience with the new equipment. Encourage feedback from employees to identify areas for further optimization in integrating new processes.

Related Posts

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs

-

How to Choose the Right Heavy Equipment Broker for Your Needs