2026 How to Choose the Right Earth Moving Equipment?

Choosing the right earth moving equipment is a critical task for contractors and project managers. Peter Lawson, a renowned expert in the construction industry, once stated, "The right equipment can make or break your project." This insight underscores the importance of understanding various equipment options before making a decision.

When selecting earth moving equipment, consider the specific needs of your project. Different tasks require different tools. For instance, bulldozers excel at pushing soil, while excavators are perfect for digging. Not every machine fits every job, and this can lead to costly mistakes. Think about the project size, terrain, and material type.

It's easy to get overwhelmed by the choices available. Often, contractors gravitate toward popular brands or models without considering their needs. This can lead to underperformance or delays. Reflecting on these factors is crucial for success in the long run. Choosing wisely allows for enhanced efficiency, better performance, and ultimately, a smoother construction process.

Understanding Different Types of Earth Moving Equipment

When choosing earth moving equipment, it's vital to understand the different types available. Loaders, excavators, and bulldozers serve unique purposes on a job site. Loaders are great for moving materials efficiently. Excavators dig deep holes and trenches, perfect for laying foundations. Bulldozers push large amounts of soil, making them ideal for leveling land.

Each type requires careful consideration. A compact excavator may fit tight spaces, but can it handle heavier tasks? A larger bulldozer might be powerful but could be overkill for small projects. It's essential to evaluate the job's scale and specific needs. Sometimes, we assume equipment is interchangeable, only to find it lacks the necessary capabilities.

Maintenance is another critical factor to ponder. Some machines require more upkeep than others. Regular servicing can be costly and time-consuming. Are you prepared for that? Choosing equipment isn't just about power; efficiency and support are just as important. Reflect on your choices, as the wrong equipment can lead to delays and budget overruns.

2026 How to Choose the Right Earth Moving Equipment? - Understanding Different Types of Earth Moving Equipment

| Equipment Type | Key Features | Best Use Case | Weight Class (Tons) |

|---|---|---|---|

| Excavator | Versatile, can dig, lift, and move heavy objects | Digging foundations, landscaping, and earthmoving | 6 - 50 |

| Bulldozer | Powerful blade for pushing large quantities of material | Clearing land and rough grading | 15 - 90 |

| Backhoe Loader | Combines a tractor, a loader, and a backhoe | Small to medium excavation and material handling | 5 - 20 |

| Skid Steer Loader | Compact size, great maneuverability, and attachment versatility | Landscaping, construction, and snow removal | 1 - 3 |

| Dump Truck | Can transport and dump large volumes of material | Transporting soil, gravel, and debris | 10 - 40 |

Identifying Your Project Requirements for Equipment Selection

When selecting earth moving equipment, understanding your project requirements is crucial. Projects vary widely in scale, complexity, and purpose. According to a report by the Construction Equipment Association, nearly 70% of project delays are attributed to improper equipment selection. This highlights the need to assess your specific needs carefully.

Evaluate the nature of the project. For example, is it demolition, excavation, or grading? Each task requires different machinery. Furthermore, project size matters. A small residential site may need compact equipment, while larger projects could necessitate excavators and bulldozers. Be aware of site conditions, such as soil type and terrain. A 2022 industry report indicated that projects on rocky ground often face higher costs due to equipment wear and tear.

Budget constraints are another factor. Equipment costs can escalate quickly. A common pitfall is underestimating the total expenses for operating and maintaining machinery. Many operators fail to track these costs, leading to unexpected financial burdens. Ensure to calculate both the initial rental or purchase price and ongoing operational costs to make the best decision. Balancing these elements is key to a successful equipment selection process.

Evaluating Equipment Performance and Efficiency

When selecting earth moving equipment, performance and efficiency are crucial.

Every project has unique requirements. It’s vital to analyze how much material can be moved per hour.

Equipment power and speed impact overall productivity. Ensure that the equipment can handle the weight and volume you need.

Efficiency means saving time and reducing fuel costs.

Tips: Look for machines with high load capacities. Consider their fuel consumption too.

A machine that uses less fuel might have a higher initial cost but saves money long-term.

Performance can also fluctuate based on terrain. Some equipment may struggle on uneven ground.

It's essential to test the equipment on-site when possible. This can reveal its true capabilities.

Sometimes, machines that appear efficient on paper don't perform as expected in real conditions.

Tips: Compare equipment based on workload and project timelines. Ask for metrics if available.

Unfortunately, not all suppliers offer transparent data. It's key to dig for information to make informed choices.

Remember that maintenance schedules impact long-term performance, too.

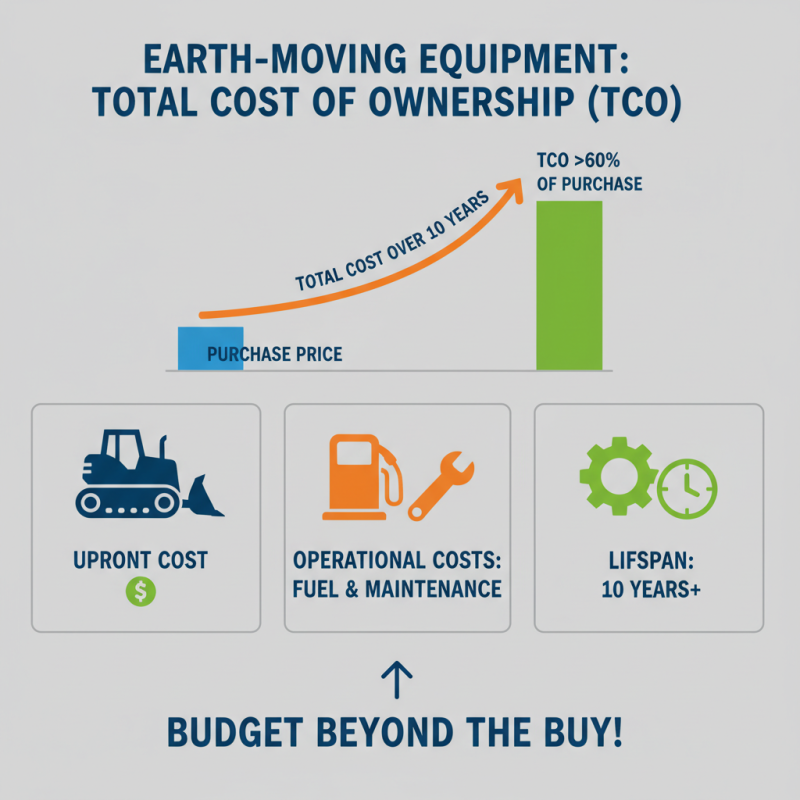

Considering Budget and Cost of Ownership

Choosing the right earth moving equipment involves thorough budgeting. The upfront cost is just one factor. According to a recent industry report, total cost of ownership (TCO) can greatly increase over time. It includes maintenance, fuel, and operational expenses. Some equipment can have TCOs that exceed 60% of its purchase price during a typical 10-year lifespan.

A common mistake is to overlook the maintenance costs. Regular servicing can add up quickly. The same report indicates that poor maintenance practices can result in 20% higher operational costs. In conclusion, consider machinery that offers reliable service intervals. This will balance efficiency and long-term expense.

Fuel efficiency is another critical factor. Equipment that consumes less fuel can save thousands annually. Some heavy machinery models demonstrate up to 30% improved fuel efficiency over older models. However, they might have a higher initial price. Weigh these factors carefully, as the cheapest option upfront often leads to regrets later. Equipment decisions require careful analysis, not just a quick purchase.

Assessing Maintenance Needs and Support Services

Choosing the right earth moving equipment involves more than just specifications. Maintenance needs are a critical factor. Approximately 70% of equipment failures stem from lack of proper maintenance. This emphasizes the importance of planning for support services when selecting machinery. Neglecting maintenance can lead to unexpected costs. In fact, 25% of companies report budget overruns linked to equipment breakdowns.

When assessing maintenance needs, consider the availability of support services. Many manufacturers offer service agreements. These can range from routine check-ups to comprehensive coverage. A study shows that 60% of construction firms benefit from preventive maintenance plans, reducing downtime significantly. However, some firms may underestimate their importance. This oversight can lead to operational inefficiencies and increased repair costs.

It's also essential to reflect on the adaptability of the equipment. As projects evolve, your maintenance strategy should too. Not all machinery has the same service requirements. Some machines may require frequent repairs. Others might have longer service intervals. Understanding these nuances is vital for effective project management. Ultimately, choosing equipment is a balance of capability and support considerations.

Related Posts

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders

-

Top 5 Second Hand Industrial Equipment Options for Your Business Needs

-

Why You Should Invest in a Plastic Recycling Machine for Your Business

-

How to Choose the Right Metal Working Machines for Your Projects

-

Top 5 CNC Machine Auctions in 2023: Unlocking Huge Savings and Opportunities