How to Choose the Right Euro Machinery for Your Business Needs?

Choosing the right euro machinery is crucial for your business’s success. The right machinery can enhance productivity and efficiency. It is vital to understand your specific needs. Various factors affect this decision.

Consider the type of work you need the machinery for. Different industries require different machines. For instance, construction may need robust equipment, while manufacturing could benefit from precision tools.

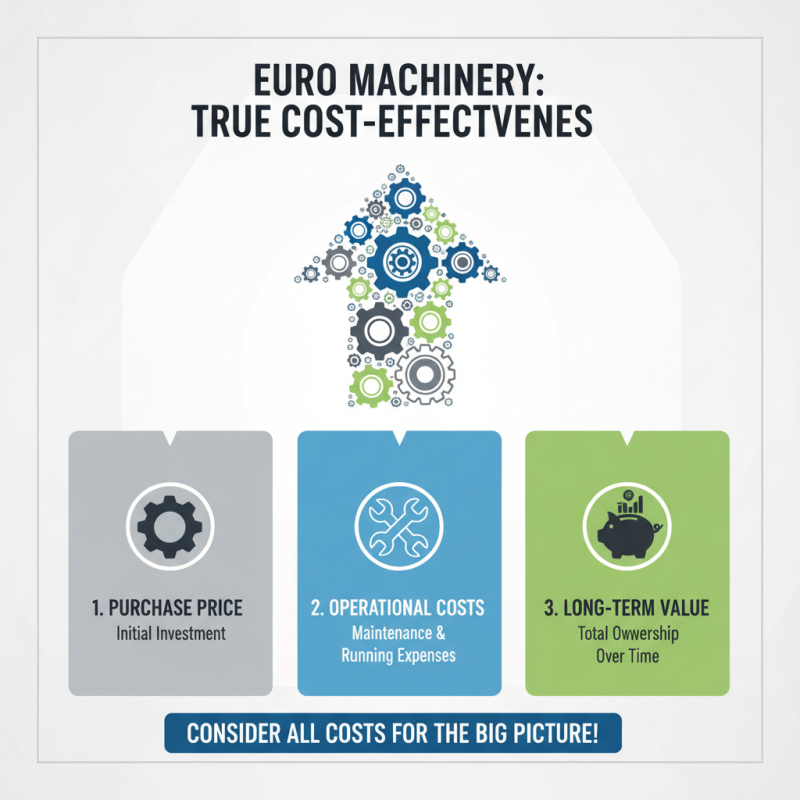

Cost is another important factor. It's easy to overspend when searching for euro machinery. However, higher price doesn’t always mean better quality. Reflecting on your budget and needs is essential. Additionally, think about after-sales support and maintenance. These aspects may influence your decision significantly.

Understanding Your Business Needs and Objectives

Understanding your business needs is crucial for selecting the right Euro machinery. Assess what tasks you need the machinery to perform. Are you focusing on production speed, quality, or versatility? Analyzing these aspects can help narrow down your options. Discuss your requirements with your team. It often sheds light on what you might overlook.

Consider your budget and maintenance needs. Some machinery might seem cost-effective upfront but can have hidden costs. Regular maintenance is key. A machine that breaks down frequently can disrupt your operations. Don't forget to think about the future. Will this machinery still meet your needs in a few years? Growth should be part of your evaluation.

Lastly, involve employees who will operate the machinery. They might offer insights that management overlooks. Understanding user experience is vital. Seek opinions and feedback regularly. This ongoing dialogue can refine your choices. Mistakes happen. Every choice is a learning opportunity. Taking the time to evaluate will pay off in the long run.

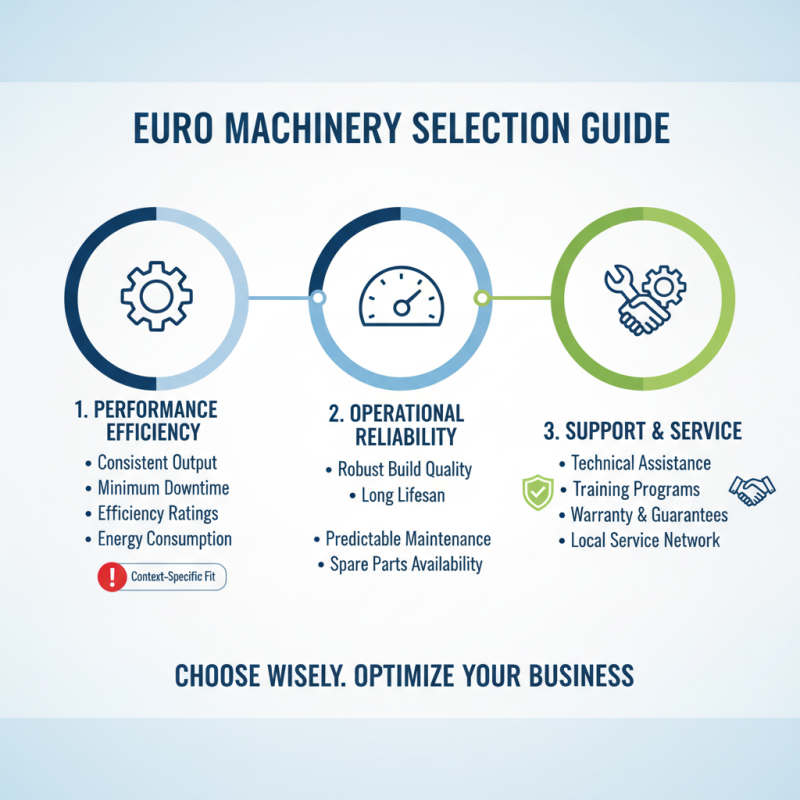

Identifying Key Features of Euro Machinery

When selecting Euro machinery for your business, understanding key features is crucial. Performance efficiency is often a primary concern. Look for machines that deliver consistent output without significant downtime. Efficiency ratings and energy consumption should guide your choice. Remember, high efficiency doesn't always mean the best fit for your specific tasks.

Durability is another essential aspect. Choose machinery designed to withstand rigorous use. Examine the materials and construction methods. Machines made from robust components generally require less maintenance. However, achieving the perfect balance between strength and weight can be challenging. Sometimes, ideal robustness may lead to cumbersome equipment that is hard to operate.

Finally, consider technology integration. Many modern machines come with smart features. These can enhance usability but may require additional training for your staff. Pay attention to the learning curve associated with advanced tech. It's vital to assess whether the benefits outweigh the training demands. Balancing these elements can be a complex task, requiring ongoing reflection about your business needs and operational capabilities.

Evaluating Cost-Effectiveness and Budget Constraints

When selecting Euro machinery, cost-effectiveness is crucial. Consider all associated costs, not just the purchase price. Maintenance and operation expenses can add up quickly. Analyzing these costs over time can help you see the big picture.

Budget constraints often limit options. It’s important to prioritize features that align with your business needs. Sometimes, a more expensive machine could lead to savings in efficiency and durability. However, avoid the temptation to stretch your budget too far. Assess if the return on investment justifies the expense.

Reflect on past purchases. Did they meet your expectations? Were there unexpected costs? Learning from previous experiences can guide future decisions. Use data to support your choices, but also trust your instincts. Choosing the right machinery is a balance of numbers and gut feeling.

Assessing Reliability and Maintenance Requirements

When selecting Euro machinery, reliability is paramount. It determines your operational efficiency. A machine that frequently breaks down can disrupt production. This leads to lost time and increased costs. To assess reliability, consider operating hours and historical performance data. Look for user reviews and industry insights. These can shed light on how machinery holds up under pressure.

Maintenance requirements are another crucial aspect. Some machinery demands regular upkeep. This can incur additional expenses and time. Understand the maintenance schedules and costs involved. Some machines may offer easy access to parts, while others may not. This can affect your team's ability to perform repairs promptly. Consider whether your staff has the skills for maintenance. If not, training might be necessary, and that could be a lengthy process.

Balancing reliability and maintenance can be challenging. You might find a highly reliable machine that has demanding maintenance needs. Or, you could choose a machine with minimal maintenance but questionable reliability. Reflect on your specific business context. Examine your resources, workforce capabilities, and production goals. Making the right choice involves careful thought and perhaps some compromises.

How to Choose the Right Euro Machinery for Your Business Needs? - Assessing Reliability and Maintenance Requirements

| Machinery Type | Reliability Rating | Maintenance Frequency (Months) | Downtime Risk (%) | Initial Investment ($) |

|---|---|---|---|---|

| Hydraulic Excavator | 8.5/10 | 6 | 10 | 150,000 |

| Concrete Mixer | 7.5/10 | 12 | 15 | 90,000 |

| Forklift | 9.0/10 | 8 | 5 | 50,000 |

| Compactor | 8.0/10 | 10 | 8 | 45,000 |

| Road Paver | 8.3/10 | 11 | 12 | 120,000 |

Exploring Supplier Reputation and Customer Support Services

When choosing Euro machinery for your business, supplier reputation is crucial. A reliable supplier often reflects quality. Look for online reviews and customer feedback. It can be tough to sift through various opinions. Focus on detailed comments rather than vague ones. Genuine experiences help in understanding reliability.

Customer support services also play a vital role. A machine is just a tool; support makes it effective. Check if the supplier offers timely assistance. Consider their response time to inquiries. A slow response may indicate inadequate support. Clarity in communication is essential. It fosters trust and ensures efficient problem-solving. Sometimes, suppliers may claim extensive support, but actions speak louder. Engage them before the purchase to assess their service quality.

Related Posts

-

Top 10 Essential Tips for Choosing Euro Machinery in Your Industry

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

-

10 Essential Tips for Choosing Machinery and Equipment in Your Business?

-

10 Essential Tips for Choosing Machinery and Equipment for Your Business?

-

Top Heavy Equipment Machinery Trends in 2026 What to Expect