2026 Top Trends in Industrial Machinery Innovation and Technology?

The industrial machinery sector is poised for significant transformation by 2026. Rapid advancements in technology are driving innovation across the industry. From automation to sustainability, these trends shape how machines operate.

Emerging technologies offer exciting possibilities. Smart machinery now incorporates AI, enabling predictive maintenance. This reduces downtime and improves efficiency. Beyond AI, the rise of IoT devices allows for real-time monitoring. Companies can gather data and optimize performance like never before.

However, with great potential comes challenges. Transitioning to advanced machinery requires skilled workers. Many companies struggle to find talent to operate new technologies. Additionally, investing in innovation can be costly. Balancing budgetary constraints with the need for progress is a common dilemma. The future of industrial machinery is bright, but it demands thoughtful consideration.

Emerging Trends in Advanced Robotics for Industrial Machinery by 2026

As we look towards 2026, advanced robotics is transforming industrial machinery. These robots enhance productivity and precision across multiple sectors. They can now work alongside human operators. This collaboration boosts efficiency and safety on the factory floor.

One emerging trend is the use of artificial intelligence in robotics. AI enables machines to learn from their environments. They adapt to new tasks quickly. However, companies must invest in training for their workforce. Human skills remain crucial in managing and operating these advanced systems.

Tips: Always evaluate the integration of new technologies. Assess whether your team is ready for these changes. Consider the potential benefits and challenges you might face. Advanced robotics can be a game-changer, but not without human oversight. Understanding this balance is vital for long-term success.

Impact of IoT Integration on Operational Efficiency in Manufacturing

The integration of IoT in manufacturing is transforming operational efficiency. Manufacturers can now connect machines and gather real-time data. This innovation helps in monitoring equipment performance continuously. When a machine encounters an issue, alerts are triggered instantly. This proactive approach reduces downtime significantly.

Tips: Keep track of data flow. Regularly check your IoT devices. Ensure they are secure and updated.

Additionally, IoT can optimize supply chain management. Sensors can predict when materials need replenishing. This minimizes delays in production. However, implementing IoT solutions comes with challenges. Not all systems integrate seamlessly. Companies may face compatibility issues. It is essential to assess the existing infrastructure.

Tips: Invest in training staff on new technology. Overcome resistance by highlighting benefits. Engage teams in the integration process.

2026 Top Trends in Industrial Machinery Innovation and Technology

| Trend | Description | Impact on Operational Efficiency | Projected Adoption Rate (%) |

|---|---|---|---|

| IoT Integration | Connecting machinery to the Internet for real-time monitoring and data analysis. | Improved predictive maintenance and reduced downtime. | 70% |

| AI and Machine Learning | Utilizing AI algorithms for optimization and decision-making in production. | Enhanced productivity and reduced operational costs. | 65% |

| Automation and Robotics | Implementing advanced robotics for repetitive tasks. | Increased efficiency and precision in manufacturing processes. | 80% |

| Data Analytics | Analyzing operational data for actionable insights. | Improved decision-making based on data-driven insights. | 75% |

| Additive Manufacturing | Using 3D printing technologies for creating components. | Reduced material waste and shortened lead times. | 60% |

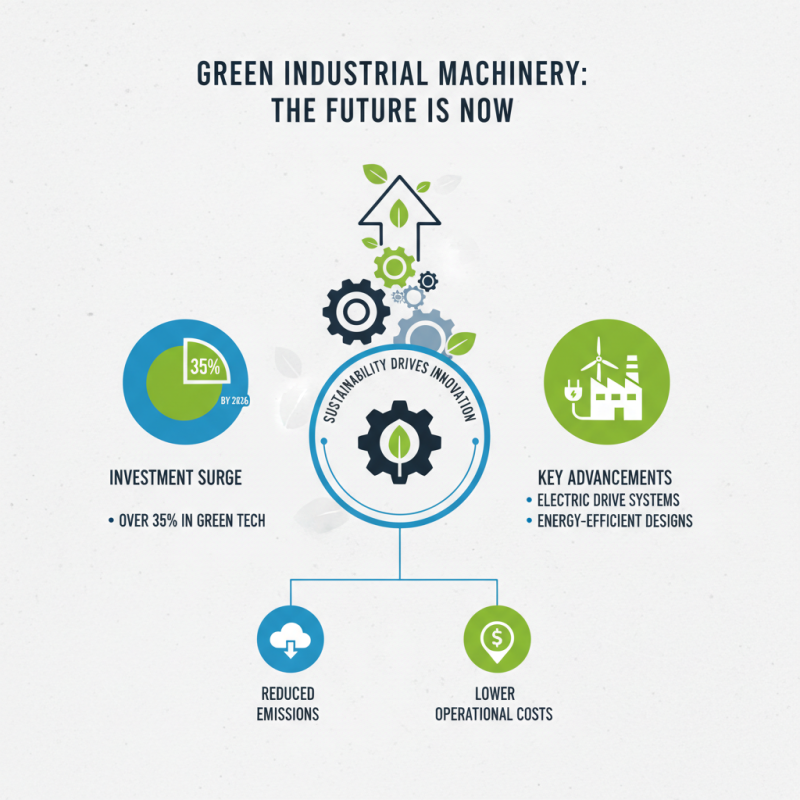

Sustainability and Green Technologies in Industrial Machinery Developments

Sustainability is becoming a core driver in industrial machinery innovation. Recent reports indicate that green technologies will account for over 35% of machinery investments by 2026. This shift reflects a growing demand for environmentally friendly operations. Companies are exploring electric drive systems and energy-efficient designs. These advancements not only reduce emissions but also lower operational costs.

However, challenges remain. Many manufacturers struggle to integrate sustainable practices into existing production lines. Transitioning to renewable resources can also involve significant initial costs. Some firms find it hard to justify the investment compared to traditional methods. There is a clear need for more training and awareness within the workforce about the benefits of green technologies.

In addition, the industry faces regulatory pressures. The EU aims for a 55% reduction in emissions by 2030. Manufacturers must adapt quickly to stay compliant. Collaboration across sectors can foster innovation. Embracing sustainability is not just a choice; it is becoming a necessity for survival in an increasingly competitive landscape.

The Role of AI and Machine Learning in Predictive Maintenance Solutions

Predictive maintenance is revolutionizing industrial machinery. With AI and machine learning, machines can now forecast potential failures. This technology uses real-time data to analyze patterns. It reduces downtime and maintenance costs. The goal is to prevent unexpected breakdowns. There’s a need for continuous monitoring. Sensors collect information about machinery performance.

However, not all implementations succeed. Some organizations struggle with data integration. Others face resistance from traditional maintenance teams. Adapting to new technology requires cultural change. Employees must learn to trust AI recommendations. It's challenging to shift from reactive to proactive maintenance strategies. Industry leaders must recognize these hurdles.

The potential benefits of predictive maintenance are significant. By catching problems early, companies can save resources. But success depends on proper data management and employee training. Organizations need to invest in both areas. It’s a balance of technology and human insight. Embracing innovation is key, but the journey is not without its obstacles.

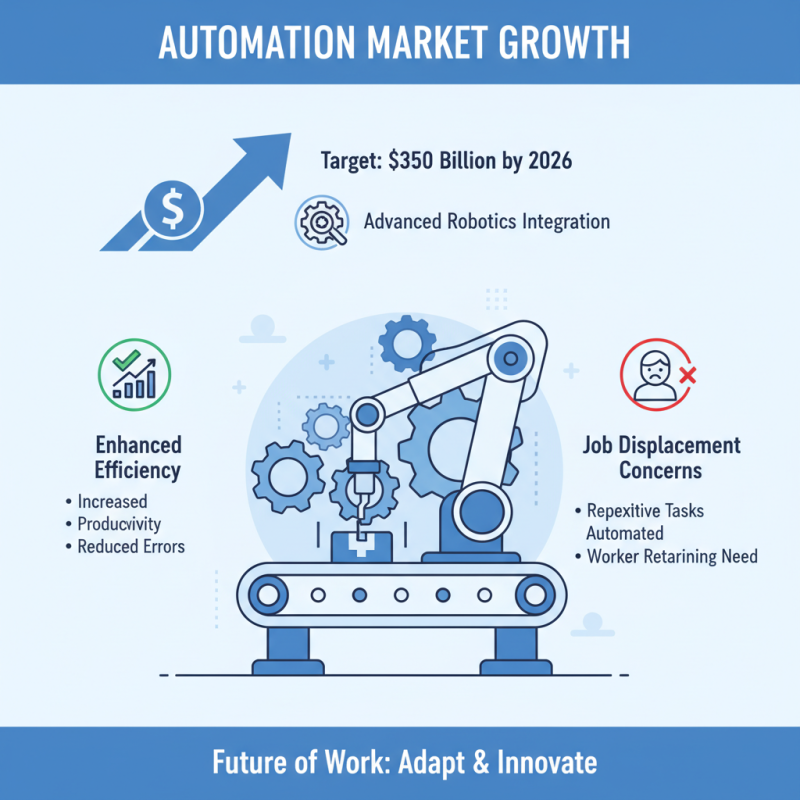

Market Trends in Automation: Growth Projections for 2026 and Beyond

The automation market is experiencing rapid growth, projected to reach $350 billion by 2026. Companies are integrating advanced robotics into their operations. This shift enhances efficiency but raises concerns about job displacement. Many workers fear obsolescence as machines take over mundane tasks.

Reports indicate that the industrial sector increasingly adopts AI and machine learning. These technologies improve predictive maintenance, saving costs and minimizing downtime. Yet, the challenge lies in the need for skilled personnel. As automation expands, a skills gap may emerge, limiting its full potential.

Additionally, sustainability is becoming vital in automation trends. Many industries focus on eco-friendly practices, yet the transition can be fraught with challenges. Investing in green technologies requires upfront costs and planning. Balancing innovation with sustainability is no easy feat, but it is crucial for future growth.

Related Posts

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

How to Choose the Right Industrial Machinery for Your Business Needs in 2025

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

-

10 Essential Tips for Choosing Machinery and Equipment in Your Business?

-

Top 5 Must Have Construction Machines for Every Builder