2026 Best Heavy Machinery Trends to Watch for in the Industry?

In recent years, the heavy machinery industry has seen significant transformations. Experts predict that these changes will shape the future of construction and heavy equipment. John Smith, a renowned heavy machinery analyst, notes, "Innovation is the lifeline of our industry." This sentiment resonates as operators and manufacturers adapt to new technologies.

Emerging trends such as automation and sustainability are driving forces in heavy machinery. Companies are increasingly focusing on eco-friendly equipment. Electric vehicles and smart technology are becoming common. These innovations promise improved efficiency but also present challenges. Industry players must invest in training and infrastructure to keep up.

Despite the focus on progress, not all trends will succeed. Some technologies may fail to deliver on their promises. Companies need to evaluate the practicality of these innovations. As the heavy machinery industry evolves, reflection on past decisions is vital for future success.

Emerging Technologies in Heavy Machinery for 2026: A Deep Dive

As we look toward 2026, the heavy machinery industry is on the verge of significant transformation. Emerging technologies promise to reshape how we approach tasks. Automation is at the forefront. Machines will operate with fewer human inputs, streamlining operations. However, this shift raises concerns about job displacement. The balance between efficiency and workforce stability must be addressed.

Another key trend is the use of advanced materials. Lightweight composites can enhance durability and reduce fuel consumption. Nevertheless, integrating these materials presents challenges. Not all existing machinery can accommodate such innovations without extensive retrofitting. Furthermore, sustainability is becoming crucial. Heavy machinery must evolve to minimize environmental impact, but implementation is not straightforward. Companies are still exploring viable pathways to achieve this.

Data analytics is also transforming heavy machinery. Real-time data collection helps predict maintenance needs. This proactive approach reduces downtime. Yet, the reliance on data poses risks. Data security and accuracy are paramount. It's essential to reflect on these challenges as the industry gears up for changes. The road ahead is promising but requires careful consideration.

2026 Best Heavy Machinery Trends to Watch for in the Industry

| Trend | Description | Impact on Industry | Innovation Level |

|---|---|---|---|

| Autonomous Machinery | Use of AI and sensors for self-driving capabilities | Increases efficiency and safety | High |

| Telematics | Real-time data collection on equipment performance | Improves maintenance schedules and reduces downtime | Medium |

| Electric Heavy Machinery | Transition from diesel to electric power sources | Reduces carbon emissions and fuel costs | High |

| Augmented Reality (AR) | Use of AR for training and maintenance support | Enhances learning and reduces errors | Medium |

| 3D Printing | On-site manufacturing of parts using 3D printers | Reduces lead time for spare parts | Medium |

Sustainability Trends Shaping the Future of Heavy Machinery Industry

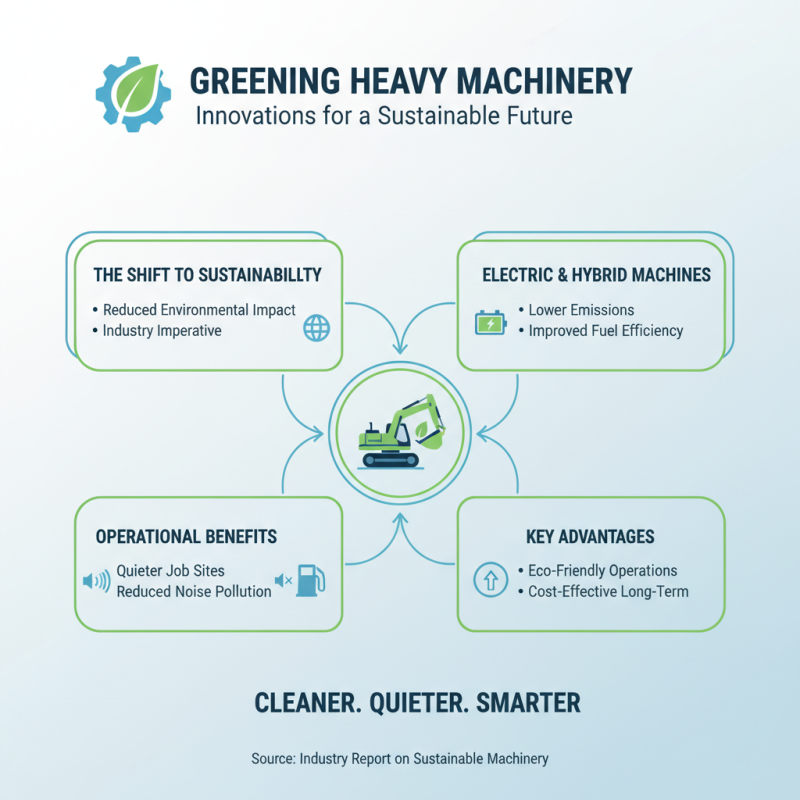

Sustainability is becoming vital in the heavy machinery industry. Companies are seeking ways to reduce their environmental impact. Innovations in electric and hybrid machinery are emerging. These machines offer lower emissions and better fuel efficiency. They operate quietly, minimizing noise pollution on job sites.

Additionally, biodegradable lubricants and eco-friendly materials are gaining attention. These advancements improve productivity while safeguarding the environment. However, the transition to sustainable practices is not seamless. Many companies struggle with the costs of new technologies. There is also a learning curve for operators unfamiliar with sustainable equipment.

Recycling and reusing machinery parts could also change the landscape. It reduces waste and conserves resources. Yet, implementing such practices requires a shift in mindset. Resistance to change may hinder progress. The journey towards a greener industry is fraught with challenges. Nonetheless, the push for sustainability is essential for the future of heavy machinery.

Increasing Automation: Impact of Robotics on Heavy Equipment Efficiency

The impact of robotics on heavy machinery is becoming increasingly significant. As automation technology advances, manufacturers are integrating robots into their operations. These systems can work alongside humans, enhancing efficiency and safety. For example, robotic arms can handle heavy materials, reducing the risk of injury.

Yet, the transition to automation isn't without challenges. Many workers fear job displacement. This issue raises questions about workforce training and adaptability. New skills are necessary as machines take over repetitive tasks. Teams must embrace change to maintain productivity.

Moreover, while automation improves precision, it may overlook certain tasks that require human judgment. For instance, some machinery operations demand creative problem-solving. This aspect cannot always be replicated by robotics. Businesses must find a balance between automation and human input. The trend toward increasing automation will reshape the industry, but it requires careful consideration of its broader implications.

Data Analytics and IoT: Transforming Heavy Machinery Operations

The heavy machinery industry is undergoing a significant transformation driven by data analytics and the Internet of Things (IoT). These technologies are reshaping how operations are managed. With real-time data collection, companies can optimize their machinery's performance. Predictive maintenance is becoming more common. It allows operators to foresee failures before they occur, minimizing downtime.

However, the integration of these technologies isn't without challenges. Not every organization is equipped to handle large data volumes. Some face hurdles in analyzing data effectively. This can lead to missed opportunities for efficiency improvements. Moreover, security concerns regarding data privacy cannot be overlooked. IoT devices can be vulnerable to cyber threats, impacting operational safety.

Additionally, while having access to data is beneficial, interpreting that data is crucial. Companies must invest in training to ensure their workforce can leverage these insights. Relying solely on technology can lead to a disconnect between human expertise and machine capabilities. Balancing the two is vital for success in the evolving landscape of heavy machinery operations.

2026 Best Heavy Machinery Trends: Data Analytics and IoT Impact

This chart illustrates the projected growth of key trends in heavy machinery operations influenced by Data Analytics and IoT from 2023 to 2026. The trends include Efficiency Improvement, Predictive Maintenance, Remote Monitoring, and Enhanced Safety Protocols.

Market Forecast: Growth Projections for Heavy Machinery Sector by 2026

The heavy machinery sector is poised for significant growth by 2026. Analysts project a steady increase in demand due to infrastructure projects worldwide. This need arises from urbanization and the push for sustainability. Countries are investing more in renewable energy, impacting machinery requirements. New technologies will play a role in shaping this sector.

In line with market trends, efficiency is key. Companies should explore advanced automation and AI integration. This could enhance productivity and reduce downtime. Machine operators must adapt to these changes. Embracing new tools can be challenging. Training programs may be required to upskill the workforce.

Tip: Consider investing in maintenance and training. Proactive measures can lead to smoother operations. Stay updated on industry news for best practices. Adaptability will define successful players in this evolving landscape. Focus is essential, yet, flexibility might be hard to achieve. Analyze your approach as trends shift rapidly.

Related Posts

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Top Heavy Equipment Machinery Trends in 2026 What to Expect

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

10 Essential Tips for Choosing Machinery and Equipment in Your Business?

-

What is Heavy Machinery and How is it Used in Industry?