2026 Best Heavy Construction Equipment for Efficient Project Management?

In the dynamic world of construction, heavy construction equipment plays a vital role in project management. The efficiency of a project often hinges on the choice of machinery. This article explores the best heavy construction equipment available in 2026.

Heavy construction equipment varies widely, from excavators to bulldozers. Each piece is designed for specific tasks, impacting overall productivity. The right machines can speed up processes and improve safety on site. However, the cost and maintenance of this equipment can be significant. This raises questions about long-term investment.

Choosing the right equipment is not just about features; it’s also about reliable performance. Many contractors might overlook vital factors, such as operator skill and equipment longevity. In essence, successful project management demands a careful balance between the selection of heavy construction equipment and the teams that operate them.

Key Features of Heavy Construction Equipment for Project Management

Heavy construction equipment plays a crucial role in project management. The right machinery can improve efficiency and productivity. Key features of this equipment include power and versatility. These traits allow operators to tackle different tasks with ease and precision. Robust engines ensure that machines perform under tough conditions.

A significant aspect is the adaptability of equipment. Projects often vary in scope and scale. Equipment that can be modified for specific tasks tends to yield better results. Moreover, user-friendly interfaces can simplify operations, reducing training time for new operators. This is an area that often needs improvement. Complex controls can lead to mistakes and delays.

Safety features are essential as well. Equipment with advanced safety systems helps reduce accidents on-site. Still, the effectiveness of these features often relies on proper usage and maintenance. Regular checks are often neglected, leading to potential risks. Ultimately, choosing equipment with the right features improves project management and outcomes.

2026 Best Heavy Construction Equipment for Efficient Project Management

Top Heavy Machinery Brands to Consider for Efficiency in 2026

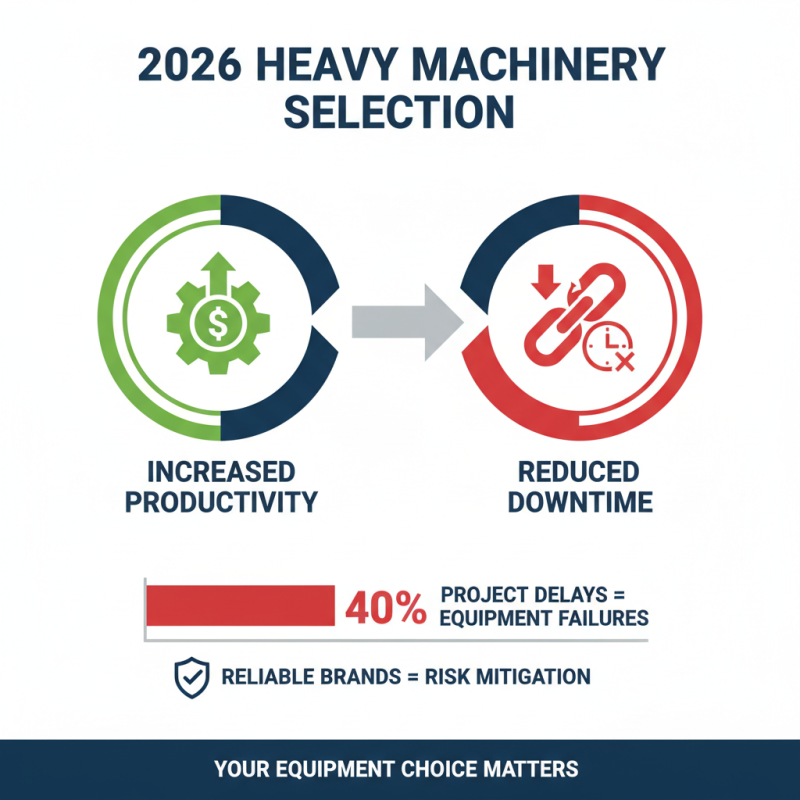

In 2026, the choice of heavy machinery can significantly impact project efficiency. The right equipment improves productivity and reduces downtime. According to industry reports, nearly 40% of project delays stem from equipment failures. Selecting reliable machinery brands is crucial for mitigating these risks.

Consider investing in electric or hybrid machinery. These options are gaining traction due to their lower emissions and reduced fuel costs. A recent study indicates that using such equipment can cut operational costs by up to 30%. These savings not only help the environment but also boost the bottom line.

Tips: Always assess equipment availability before a project starts. Delays can arise from not having the right machines on site. Additionally, conduct regular maintenance checks. A well-maintained fleet can prevent 25% of unexpected equipment failures. Choose wisely and ensure your projects run smoothly.

Comparison of Equipment Types: Excavators, Bulldozers, and More

Heavy construction equipment is vital in project management. Excavators, bulldozers, and other machinery play essential roles. Each type has its strengths and limitations.

Excavators are powerful and versatile. They excel in digging, lifting, and demolition tasks. Their rotating cab allows for better visibility and maneuverability. Yet, they can struggle in tight spaces. Proper training is important to maximize their capabilities.

Bulldozers, on the other hand, shine in moving large quantities of material. Their wide blades make them ideal for grading and clearing. However, their size can be a drawback on narrower job sites. Operators must be cautious in such situations.

**Tips:** Always assess the site before choosing equipment. Consider space, terrain, and project needs. Training your team can prevent costly mistakes. Invest time in skill development. It pays off in efficiency. Balancing equipment choice with project demands can lead to smoother operations.

2026 Best Heavy Construction Equipment for Efficient Project Management

| Equipment Type | Weight (lbs) | Max Dig Depth (ft) | Horsepower (hp) | Fuel Capacity (gal) | Average Cost ($) |

|---|---|---|---|---|---|

| Excavator | 25,000 | 20 | 150 | 50 | 100,000 |

| Bulldozer | 30,000 | 8 | 200 | 60 | 150,000 |

| Backhoe Loader | 15,000 | 14 | 100 | 40 | 75,000 |

| Wheel Loader | 20,000 | 10 | 175 | 50 | 120,000 |

| Skid Steer Loader | 8,000 | 8 | 75 | 20 | 50,000 |

Innovative Technologies Enhancing Heavy Construction Equipment Performance

Innovative technologies are transforming heavy construction equipment, driving efficiency in project management. According to a recent industry report, the adoption of telematics has surged by 30% over the last five years. This technology allows for real-time monitoring of equipment performance and location. By leveraging this data, project managers can optimize resources and reduce downtime.

Remote diagnostics is another key innovation in heavy machinery. This feature enables immediate identification of potential issues, which can prevent costly delays. A study revealed that companies using remote diagnostics experienced a 25% decrease in maintenance costs. However, not all firms are adapting quickly enough. Many still rely on outdated maintenance schedules rather than real-time data analyses.

Furthermore, automation in construction equipment is reshaping workflows. Autonomous vehicles can perform repetitive tasks, minimizing human error and increasing safety. Yet, the initial investment for these technologies can be high, and not all companies are willing to take that risk. As a result, some projects may fall behind, struggling to catch up with competitors who have embraced innovation.

Maintenance Best Practices for Maximizing Equipment Lifespan and Efficiency

Proper maintenance of heavy construction equipment is crucial for maximizing both lifespan and efficiency. Regular inspections help identify potential issues early. Operators should be trained to recognize unusual sounds or vibrations while using the equipment. Ignoring these signs can lead to costly repairs and project delays.

Routine maintenance tasks include checking fluid levels, inspecting filters, and ensuring all components are functioning correctly. Neglecting these aspects often results in unexpected downtime. Operators might feel overwhelmed, leading to shortcuts that compromise equipment integrity. It’s essential to prioritize these maintenance checks, even when schedules are tight.

Documentation of maintenance practices can be beneficial. Keeping a detailed log helps track the equipment’s health over time. However, not all teams follow this habit. Skipping documentation leads to gaps in understanding equipment needs and performance. A few minutes spent on record-keeping can save hours later. Implementing a structured approach ensures that all equipment runs smoothly, maintaining efficiency on every project.

Related Posts

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

Top 10 Best Construction Machines for Every Project?

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

2026 How to Choose the Right Earth Moving Equipment?

-

Top Heavy Equipment Machinery Trends in 2026 What to Expect